NIPS

Beschreibung

The DESION Norm Inspection System

NIPS automates the process of necessary quality control of high-visibility clothing after washing, based on the electronic processing of images and machine learning.

What Does our Technology Accomplish?

Textile service providers require constant quality assurance after washing their textiles. Through DESION NIPS the recognition of deviations in color and reflection is automated and carried out in consistently high quality. Our camera system can recognize a multitude of textile defects on fabric and reflective stripes.

Integrated Optical Quality Control

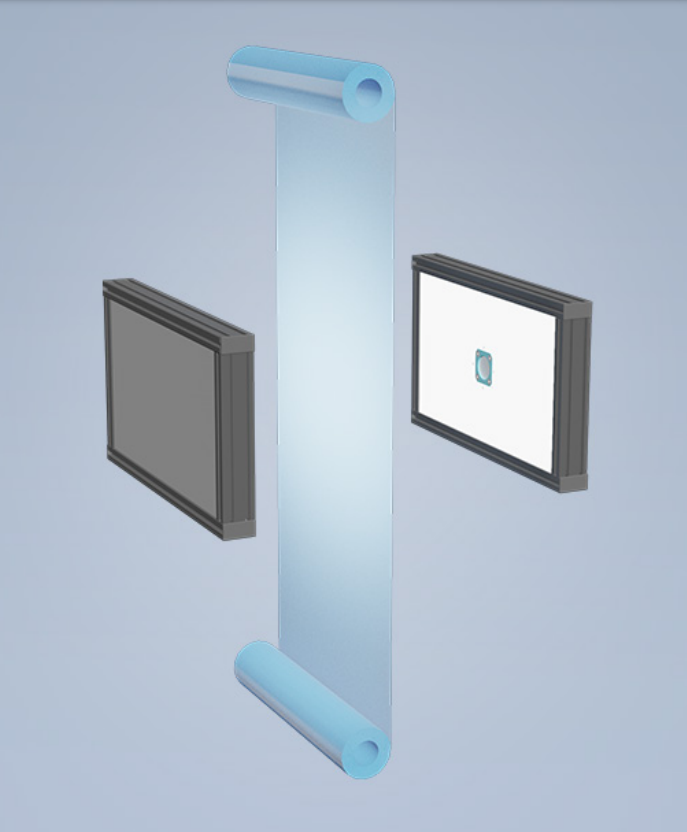

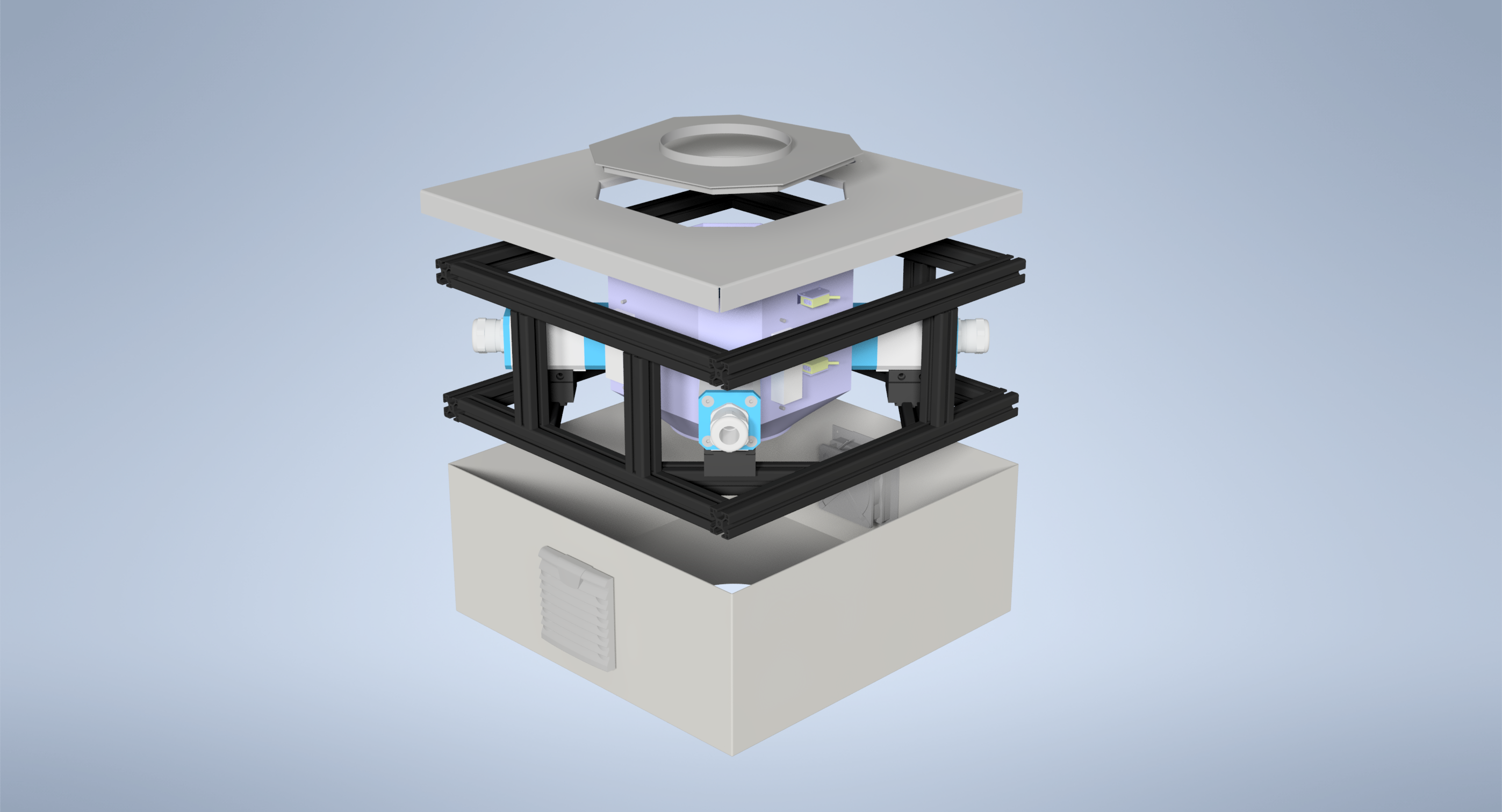

Garments, after washing and finishing on individual hangers, pass by our lights with integrated cameras, where photos are taken of the front and back (2 - 4 camera setups). Our software analyzes these photos in real time and transmits the results to the control software, which then sends the garments to selected stations in the quality control process. The results of each inspection are stored in the system and build a valuable collection of data. This database enables the customer to perform further analysis and optimization not only of the system itself but also the internal processes.

What Can it Detect?

Following characteristics can be detected by our system:

- Color deviation

- Reflective strips (including strip type & damages)

- Material types (e.g. different fibers, weaving)

- Clothing types

- Holes

- Different kind of stains

- Brightness deviation

What Can it Be applied for?

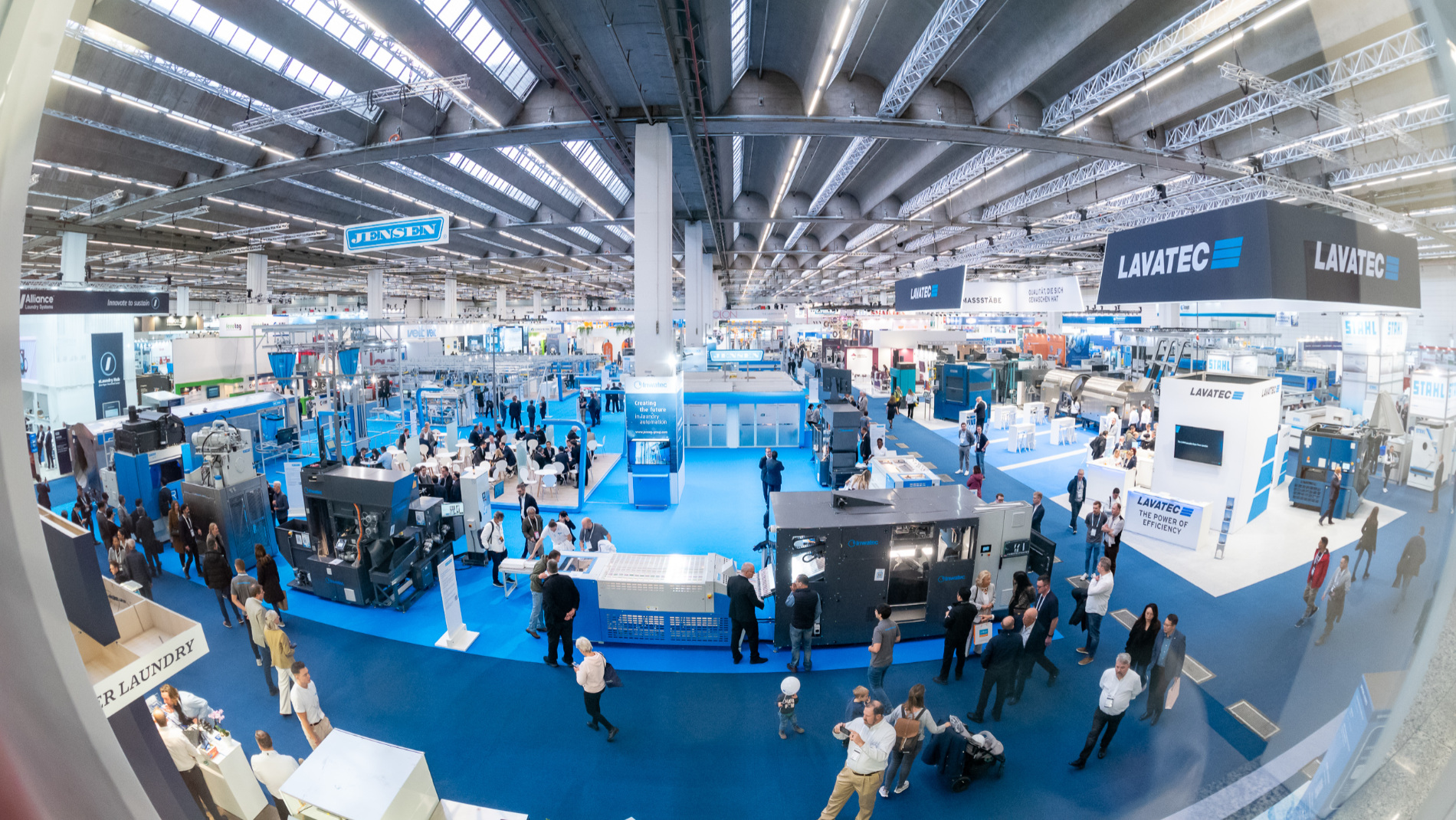

In addition to the washing textile industry, other industries can also benefit from our technology. NIPS can be seamlessly embedded in existing systems and processes for advanced visual quality assurance.