Rail transport system Daniela and feeding machine Therese

Daniela is a rail transport system for the transport of the linen inside of a laundry. It's characteristical usage is the transport of large pieces like sheets or blankets from the washing machine to the feeding machine. With Daniela, the following tasks can be done:

● Hanging up of the pieces in one or two clamps

● Manual or automatic delivery to a feeding machine

● Sorting of pieces

● Storing of pieces

For hanging up of the linen in one or two clamps, two modes of operation are possible:

1. A piece is hanged up with one edge (one clamp):

Usually, above a laundry container an edge of a piece is inserted into a clamp of the transport system. The system pulls the piece automatically out of the container and stores it in the storage. Should a piece be inserted incorrectly or can it not be pulled out of the heap of linen, it is possible to eject it out of the clamp.

2. A piece is hanged up with two edges (two clamps):

Above a laundry container an edge of a piece is inserted into a clamp of the transport system. The system pulls the piece automatically out of the container and the clamp stops in an optimal position to take the second edge and put it into another clamp of the transport system. Then, the piece is transported to the storage. Is it the clamps' turn, they are transported to the feeder.

These operating modes have the following advantages:

● The clean linen is transported from the washing to the ironing line in a height of approximately 5 meters, so no laundry containers are used and there is more empty space available.

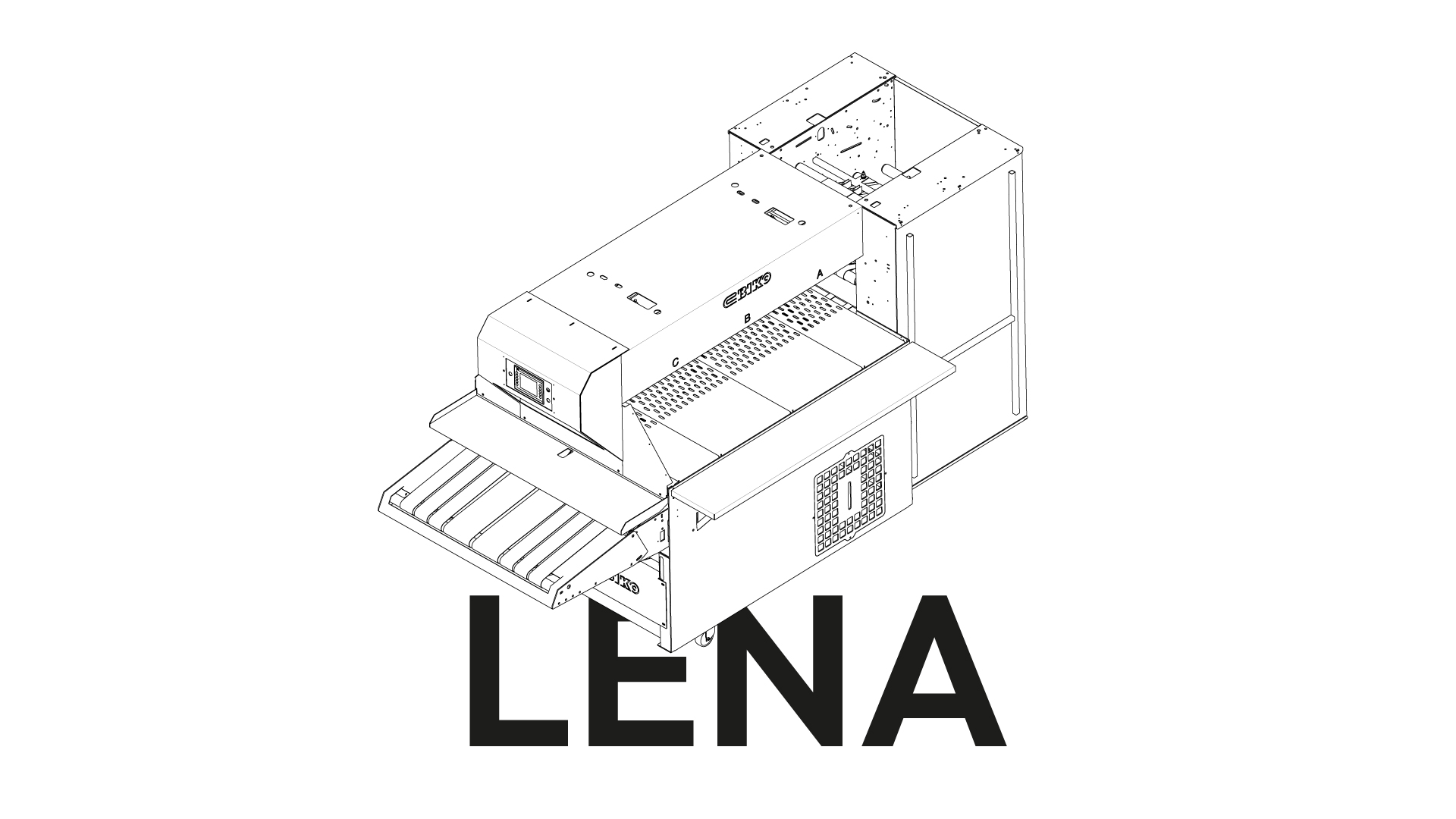

Therese

Therese is a feeder for large pieces (up to 3000 mm long and 3200 mm large) that can achieve highest quality standards. It is available as a machine with one or two lanes.

The sheets are fed directly via rail transport system Daniela or decentralized with two clamps per sheet. The number of loading stations is adapted to the necessary achievement. Photocells supervise the process of spreading. Thus the spreading can be controlled exactly and adapted to each piece. The spread piece is presented in front of an illuminated wall to be checked and possibly sorted out. The spreading process can take place on a height of 2.3 to 2.9 meters (depending on the height of the machine), whereby the depth of the shaft under the machine can be reduced to a minimum respectively avoided completely.

The control of the machine is done by a programmable microprocessor (PLC). The control has also an Ethernet connection that can be used for communication. The standard machine can run a 1000 different programs. All of these programs can be adjusted by the customer. The operation is done by a touch screen. It is possible to connect the control to a production data acquisition system. As an option, the company BIKO offers a remote maintenance via internet or via analogue modem.

The theoretical maximum production of the Therese is 1000 pieces / hour (with one lane).