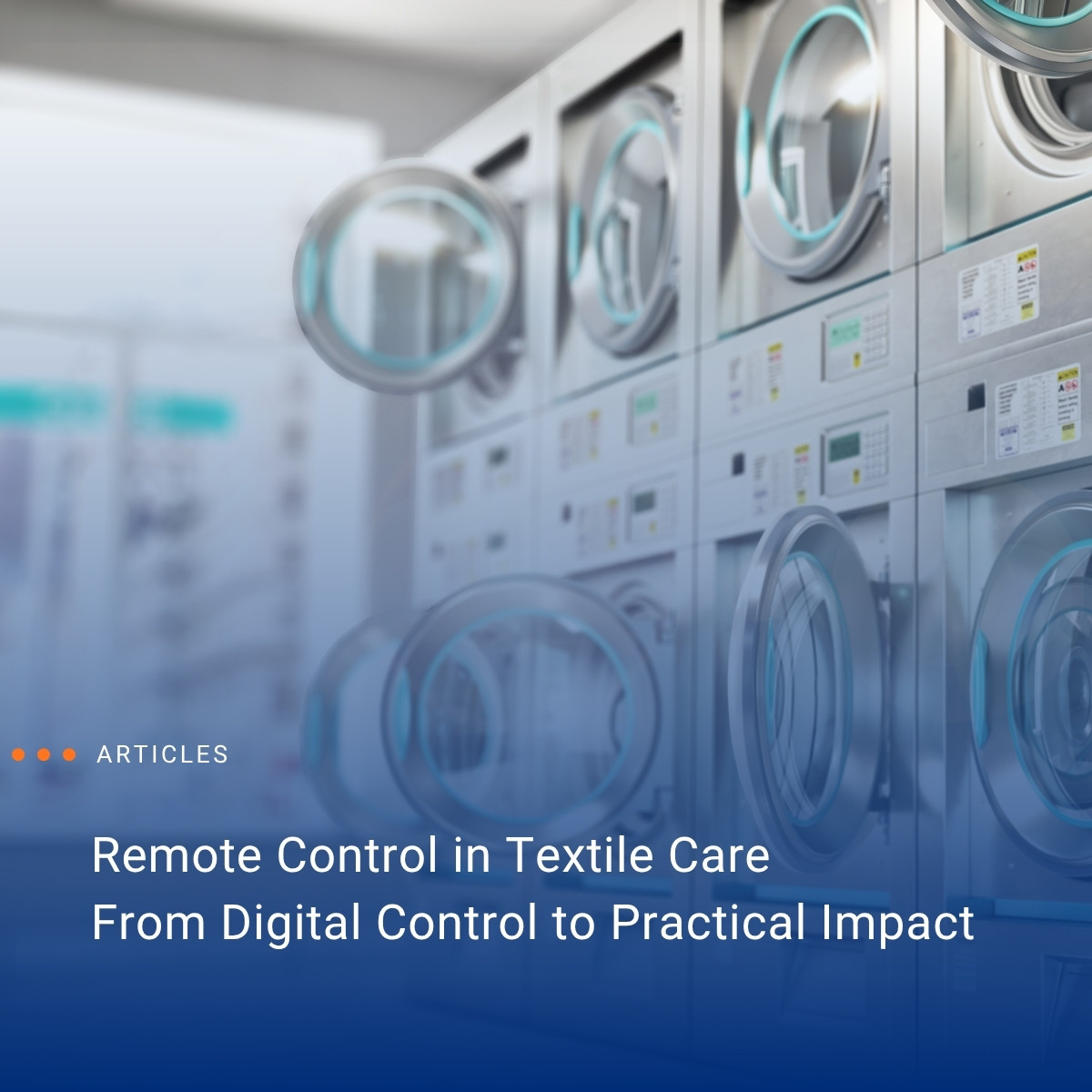

How are automation and robotics transforming textile care? Explore smart technologies that speed up processes, ease workloads and ensure consistent quality.

Automation & Robotics & Handling: All Content at a Glance

Deepen your knowledge: discover all relevant content – in various formats – prepared exclusively for you with practical relevance.