Gottlob Stahl Wäschereimaschinenbau GmbH

Gottlob Stahl Wäschereimaschinenbau GmbH

Ulmenstraße 24

71069 Sindelfingen

Germany

Telephone+49 7031 73840

Fax+49 7031 738490

About us

Gottlob STAHL Wäschereimaschinenbau GmbH is a Swabian family business with a 111-year history. STAHL develops and produces its machines exclusively in Germany and sells them worldwide. STAHL itself also takes over the complete service for the machines. The product range extends from industrial washing machines and dryers, trough ironers, folding machines and disinfection sluices to the appropriate accessories for all product areas.

Our product groups

Keywords

- Trockenschränke, drying cabinets

- Faltmaschinen, folding machines

- Waschmaschinen, washing machines

- Wäschetrockner, laundry dryers

- Muldenmangeln, flatwork ironers

Our Products

High-speed ATOLL industrial washing machine

The allrounder.

The robust and durable STAHL ATOLL washing machine in 15 sizes from 6 to 115 kg is suitable for all textiles and applications. You can now wash everything in just one washing machine.

Suitable for: Towels and bathrobes, tablecloths and serviettes, bed linen, outerwear and wet cleaning, mops and cloths, dirt-trapping mats and pet blankets, fire brigade and rescue service clothing, PPE and equipment items such as respiratory protection masks, kitchen linen, curtains and drapes and much more!

Advantages of the ATOLL

- Energy efficient

- Water saving

- Short washing times

- Robust & durable

- Kind to textiles

- Large loading opening

- Service-friendly machine design

- Suitable for connection to automatic liquid detergent dosing system

- Easy operation with all parameters freely programmable, e.g. temperature and temperature hold time

Highlights of the professional ATOLL washing machine

Intuitive operation via large touch display

Our extremely flexible FREEpro touch control unit allows you to use the ATOLL in many different ways. In addition to 99 freely programmable washing programs, you also have the option of adjusting various parameters during the washing process, including temperature, holding time, water level, speed, rinse time, spin time and spin speed.

The washing solutions that come as standard include programmes at a variety of temperatures and with various rinse processes and spin speeds, as well as single, double or triple soak processes. The STAHL washing machine control unit includes as standard washing programme packages for all applications and industries, e.g. for: Hotels, cleaning services, care homes, fire brigades, wet cleaning programs for textile cleaning, equestrian sports and much more.

Of course, you can also use the FREEpro touch control unit to store and select thermal and chemo-thermal disinfection programs which are compliant with the guidelines of the Robert Koch Institute (RKI).

The innovative control unit also gives you the options of treating mops and towels with cleaning agents or surface disinfectant directly in the machine so that they are ready for use again straight after washing. Not only do you save on costs, you also save valuable time.

High-quality detergent compartments made from stainless steel

Stainless steel detergent compartments prevent the washing powder from clumping together and always remain hygienically clean.

Large doors at ergonomic height

The large doors are located at an ergonomic height and make it easier for your staff to load and unload the machine, which prevents bad posture. The fill opening is especially large to make work easier.

Automatic load size detection

The maintenance-free PTS 3 Power Transmission System developed by us only consumes as much energy as is actually needed for the respective activity, e.g. power consumption during spinning decreases the drier your laundry becomes, or if the ATOLL commercial washing machine is not fully loaded. The PTS 3 with its trendsetting ultra-efficient motor reduces current spikes, detects and controls unbalance situations, ensures quiet operation and features continuously adjustable washing and spinning rotation speeds as well as gentle starting and wear-free braking of the drum without the use of mechanical braking components. What PTS 3 means for you is flexible, economical, safe and innovative washing.

Our intelligent WRS water regulation system continuously monitors the water level and adapts to the circumstances automatically. For example, the ATOLL recognizes when there isn’t a full load, meaning less water is used. This means that STAHL’s commercial ATOLL washer extractor machines always have the lowest possible water consumption and are the most economical washing machines for your commercial purposes.

Generously dimensioned stainless steel drain valve

The stainless steel drain valve ensures a reliable workflow even when there is coarse dirt in the laundry and can be accessed from the front via a large service flap.

The drain valve is developed and produced by us and is step-shaped, which prevents dirt from being deposited and foreign bodies getting stuck in it. This guarantees you a reliable and economical workflow without the need for time-consuming maintenance.

The stainless steel drain valve in our washing machines is controlled by water or air and therefore remains closed even if there is a power failure, which would otherwise result in the water being lost, and you are having to restart the washing process. This promises operational reliability when using STAHL commercial washing machines.

Another advantage for you is that they are wear-free, as there is no rubber diaphragm, ball or strainer is installed in the STAHL stainless steel drain valve. As a result, you benefit from a reduction in maintenance costs.

Stable drum with large funnel perforations

The STAHL drum is suitable for washing all types of textiles, even heavily soiled mops or dirt-trapping mats, in just one machine without coarse dirt remaining in the drum after the wash cycle. In addition, due to the funnel perforations, a lower spin speed is required for a residual moisture of approx. 48%.

The STAHL stainless steel washer drum has funnel-shaped and gently curved outwards-facing perforations. This means that your laundry is very gently handled, and the desired friction effect increases within the laundry, but decreases on the metal. The number of the holes and their size has been optimised in order to provide you with the maximum possible level of efficiency. They ensure that any suds are discharged quickly, which is important, especially during the spin cycle, in order to achieve the desired residual moisture level of approx. 48% quickly with minimal energy consumption. During the spin cycle, the laundry is pressed onto the funnel perforations. If the drum perforations are too small, more power is required due to a higher spin speed and longer spin cycle time. This leads to greater energy consumption and more wear on the bearings and spring/shock absorber system.

With the STAHL drum perforations you also benefit from the fact that no coarse dirt from mop covers, dirt-trapping mats, kitchen linen and pet blankets remains in the drum after the wash cycle. Depending on the washing machine size, the ATOLL is equipped with between four and six drum paddles, which are also perforated. This paddle technology ensures greater movement and quicker immersion of your laundry, thus saving you time and energy. Another benefit of our drum is the dome on the rear side. This reduces the area that does not come into contact with the laundry compared to conventional systems. The quantity of unused water is therefore reduced, and this also saves you water and energy.

T 232-246 laundry dryers

The flexible.

The energy-saving, wear-free STAHL laundry dryer is available in five sizes from 8 to 40 kg and is suitable for all textiles and industries.

Suitable for: Towels and bathrobes, tablecloths and serviettes, bed linen, outerwear and wet cleaning, mops and cloths, dirt-trapping mats and pet blankets, fire brigade and rescue service clothing, PPE and equipment items such as respiratory protection masks, kitchen linen, curtains and drapes and much more!

Advantages of the T-Series

- Energy efficient with air recovery/circulation

- Short drying times with residual moisture monitoring

- Maintenance-free direct drive without V-belts

- Kind to textiles

- Robust & durable

- Quiet

- Large loading opening

- Service-friendly machine design

- No drum support rollers or drive rollers

- Easy operation & all parameters are freely programmable

- Large stainless steel lint filter

Highlights of the T-Series

Maintenance-free direct drive

All STAHL T 232 to T 246 laundry dryer models have a unique, absolutely maintenance-free direct drive. It functions without wearing parts such as drum support rollers, V-belts or drive rollers. The wear-free motor contributes to the fact that the machine only consumes as much energy as the respective process requires. If the dryer runs at only half capacity, the energy consumption is automatically reduced.

30% energy saving thanks to unique plate heater exchanger

The integrated plate heater exchanger ensures an optimum energy balance. The recycled warm air first flows over a heat exchanger, which then uses the stored heat to preheat the cool fresh air drawn in from outside. With this optional piece of equipment, the tumble dryer requires even less energy. This revolutionary system with its high savings potential is only available in STAHL dryers.

Intuitive operation with residual moisture sensor

The proven FREEpro microprocessor control unit, which is built the same for all STAHL laundry machines, is intuitive and easy to use. It includes many common standard programs (e.g. full dry, delicate laundry, ironer-damp). All parameters can be individually programmed. The current drying process is shown on the display. A sensor provides reliable detection of residual moisture and prevents the textiles from overdrying. This means the dryer only runs as long as necessary. This saves time and money and also protects the laundry. Thanks to the flexible design of the FREEpro control unit, you can change different parameters at any time during the drying process. These parameters include temperature, residual moisture and drum speed. This enables you to work flexibly at all times, even during the running laundry process.

Large stainless steel lint filter

A large surface area lint filter made of stainless steel is located underneath the drum and can be easily and conveniently cleaned from the front. The lint filter is screwed directly onto the housing so that no lint can pass under the screen frame.

Radial air flow and high-quality stainless steel drum

Radial air flow provides exceptionally fast, gentle and thorough drying. The hot air is blown diagonally, downwards through the fully perforated stainless steel drum. The temperatures remain the same everywhere. The drum reversal supports the radial air flow by changing the way the laundry falls, ensuring sensitive textiles are dried evenly in the shortest possible time. Unlike the longitudinal air flow principle, with radial air flow the laundry is not pressed against the front of the glass window.

Smart air recovery/circulation

The standard air recovery process saves the environment and operating costs. This is because this smart process uses and recycles approximately 50 per cent of the used air. Only the water vapour is removed during the drying process. The dry air flows over the heater and back into the drum as hot air.

Drying cabinet TS 1300

The innovation.

The flexible and energy-saving STAHL TS 1300 drying cabinet is suitable for the gentle drying of all types of textiles and equipment.

Suitable for: Fire brigade clothing, emergency services textiles and other PPE, boots, gloves, breathing masks, regulators, helmets, fire hoses, caps, ski boots, ski jackets and trousers, outdoor and hiking clothing, hiking and sports shoes, wetsuits, towels and bathrobes, outerwear, mops, life jackets, cloths and much more!

Advantages of the TS 1300

- Energy efficient thanks to condensation drying

- 230 V power supply and maximum 3 kWh power consumption

- Short drying times

- Stepless temperature control from 20-80°C with STAHL FREEpro control

- No air exhaust required

- Plug-in holders for boots, gloves, helmets and much more

- Ozone lamp

- Quiet

- Robust & durable

- Easy to use

- Kind to textiles

Highlights of the TS 1300

Maximum power consumption 3 kWh with only 230 V connection

The high-performance STAHL drying cabinet only required a 230 V power outlet and can be placed anywhere. The drying cabinet has a maximum power consumption of 3 kWh.

Efficient condensation drying

The TS 1300 is an efficient condensation drying cabinet that does not require a window or core drill hole to remove the moist air. The condensation can either be fed into the buildings drainage system or into a canister. The drying cabinet is universal and can be used without construction work in all spaces without risk to the building structure.

Freely programmable temperature control from 20-80°C

The TS 1300 drying cabinet is equipped with the STAHL FREEpro control system as standard. This allows up to 99 programmes to be individually preset. The temperatures are infinitely adjustable between 20°C and 80°C. In addition, the intervals at which the drying cabinet reaches the desired temperature levels can be flexibly selected. This optimises the fast and gentle drying of all textiles and items of equipment. The high temperature of 80°C is also ideal for perfect activation of the impregnation.

Plug-in holders for boots, gloves and much more

The drying cabinet offers plenty of space for your equipment: For example, the STAHL drying cabinet can dry up to eight firefighter jackets and trousers simultaneously. It can also be used to dry hiking and outdoor textiles, as well as ski clothing and wetsuits. Thanks to its modular design, additional holders can be attached to the plug-in system without the need for tools. This allows the drying cabinet to be configured individually and adapted to suit your needs. With the matching holders, boots, helmets, masks, regulators, gloves and even fire hoses can be easily dried in the drying cabinet.

Hygienic drying with ozone

As an option, the TS 1300 can be equipped with an ozone lamp. This guarantees hygienic drying, as the harmless amounts of ozone reduce germs and odours.

Further Features

- Robust powder-coated steel design

- Large side opening doors

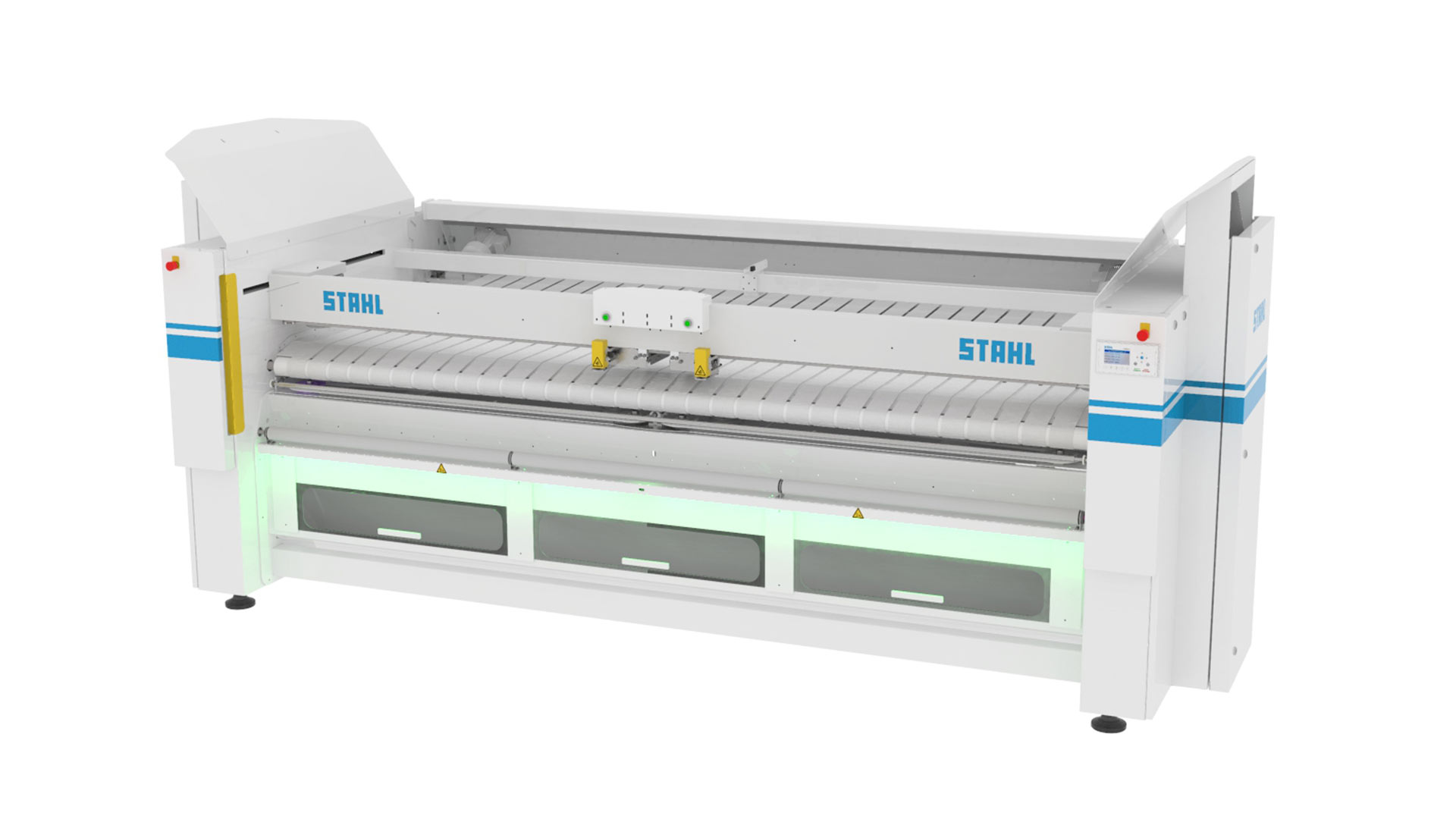

SERVANT laundry feeding machine

The service-friendly.

The SERVANT feeding machine guarantees quality and cost-savings through the manual feeding of flat laundry items into STAHL flatwork ironers on several lanes as well as through the automatic feeding on one lane with up to three feeding positions.

Suitable for: Bed linen, bed sheets, tablecloths, table runners, serviettes, chair covers, dishcloths, aprons and other flat laundry items!

Advantages of the SERVANT

- Performance-enhancing

- Higher feeding quality of all textile sizes

- More ergonomic laundry feeding into the ironer

- Automatic 1-lane chamber feed

- Up to three feeding positions

- Low-maintenance

- Easy to use

- Service-friendly machine design

Highlights of the SERVANT

Longer feeding table with suction

The suction table with its long feeder belt facilitates the work of the operator when manually feeding laundry into the flatwork ironer. It holds the laundry in position until it is transferred to the flatwork ironer, prevents slippage and increases productivity as a result.

Suction devices with spreading brushes

A feeder device with a strong suction function is located under the feeding table, which pulls at the bottom end of the inserted piece of laundry. The connection of the suction device to the switchable spreading brush system creates a better spread of the textile, resulting in a more effective feeding process. Another advantage of the feeding machines with suction devices is that this option prevents the textiles from coming into contact with the floor, thus improving hygiene. In addition, with the feeder device you save on construction costs, as the feeding machine can be operated without the need to build a laundry trench.

Easily accessible, large fibre filters

The suction system outlets are equipped with large fibre filters to ensure good air quality, free of lint. The filter system is easy to clean when standing via large side doors.

Spreading conveyor and upper spreading brushes

The spreading conveyor consists of tightening bands mounted above the feeding table which pull the textiles without creasing them. Any smoothing faults that may have occurred are remedied by means of upper spreading brushes that can be switched on as required.

Fast clamp placement for up to three operators simultaneously

As an option, the Servant feeding machines are available with a clamp feeding system, which allows only one operator to feed approx. 300 large pieces of laundry perhour on one lane. If all three feed positions are occupied, the clamp feeding systemenables an output of approx. 500 large items per hour, as the gripper mechanismmoves between the three feed positions. The feeding grips close automatically andguide the laundry to the vacuum table at precisely the right tension.

KOMBIFOLD terry cloth folding machine

The accurate.

The STAHL KOMBIFOLD terry cloth folding machine folds, sorts and stacks terry cloth goods quickly and precisely up to a maximum size of 180×115 cm.

Suitable for: Towels, shower mats, blankets, aprons, fitted sheets, t-shirts, undervests and much more!

Advantages of the KOMBIFOLD

- Reduce staff costs

- Fast and uniform folding of up to 1800 items per hour

- Easy to use

- Only one person required to feed unsorted laundry

- Gentle folding of textiles

- Individual configuration of discharge belt

- Automatic laundry detection

- Service-friendly machine design

Highlights of the KOMBIFOLD

Fold up to 1800 items per hour with only one person

The KOMBIFOLD terry cloth folding machine is the right investment for you company – launderette, hotel, hospital, wellness centre – if large amounts of terry cloth goodsare folded hours at a time by your staff. You will save time, effort and money and also save on staff.

Fold three different unsorted towel sizes simultaneously

The KOMBIFOLD terry cloth folding machine gently folds, reliably sorts, and accurately stacks three different sizes of terry towels at the same time. Your operating staff lay the unsorted terry towels on the feed conveyor in rapid succession. The folding machine checks the shape of the towel and folds them in the selected folding pattern using a patented air folding combination, sorts them by size, and then stacks them accordingly.

Easy to control via large display

The FREEpro touch freely programmable control unit allows you to create your own bespoke folding programmes and simply select or change them at any time. If your textiles are not fed in correctly, the folding machine rejects the unfolded laundry and in the event of an operating error, it stops immediately. This means the folding machine is always safe and easy to operate.

Ergonomic, user friendly & flexible design

Unsorted terry cloth items can be fed conveniently into the terry cloth folding machine by just one person while standing. The dry laundry folding machine has a central discharge belt fitted as standard to the right side of the machine which returns the items to the operator at an ergonomic height once the programmed number of stacks has been reached. Depending on your specific requirements, this conveyor belt can also be fitted to the left side of the machine. The finished laundry stacks can also be conveyed to the rear of the machine and, if required, can also be connected to a central discharge belt. These adjustments can also be made retrospectively, providing you with maximum flexibility.

Our Contact Persons

Uwe Stahl

Managing Director

Sebastian Hatz

Sales

Head of Division