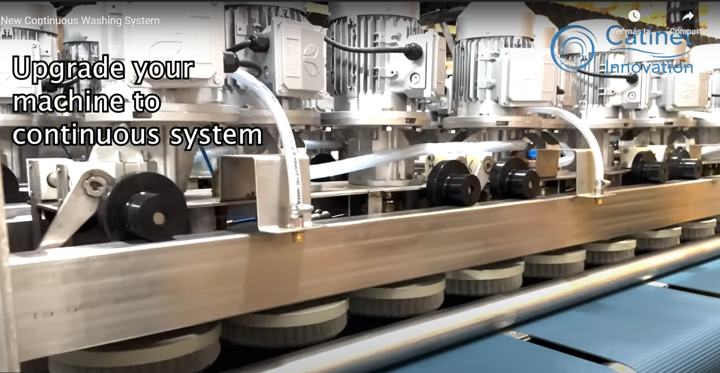

Catinet TOTAL Continuous washing process

Description

The only equipment on the market currently that with a single machine performs the full treatment of the carpet with a professional quality.

This washing equipment performs the following functions: dust + washing + spin, on a single machine without noise or vibration.

We have TOTAL models at your disposal, from a mini carpet washing installation that only needs 15m2 to an industrial carpet washing one.

The first dust remover process is made in the bottom of the machine. The 80% of the dust is collected in the drawers. And the last 20% with the exterior vacuum cleaner. When the carpet comes out 1 meter the process of washing which covers the four stages of the washing train, can be started.

First stage: The carpet is shampooed; the flow of the sprayers can be varied according to the carpet’s thickness. A variable flow-rate pump feeds the detergent directly from the shampoo container.

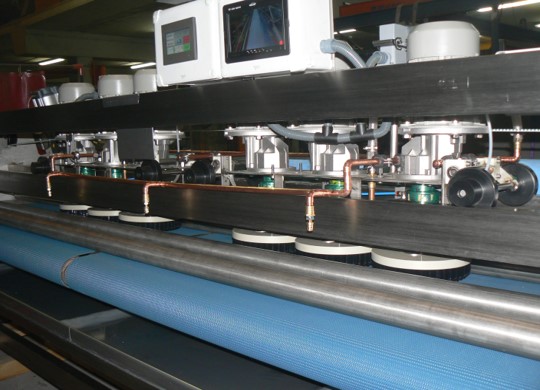

Second stage: This is the area where the brushing process take place. Twelve brushes on slides move from one side to the other of the washing train. These slides are equipped with a compressed air system for regulating the pressure on the carpet that can be adjusted from 0 to 60 kgs. per slide. The brushes’ direction of rotation is changed from the control panel, thus extending the brushes’ service life by preventing bristle deformations.

Third stage: In this area, the carpet is thoroughly rinsed and combed.

Fourth stage: during this stage, the carpet is rolled automatically and is ready for entry, without any additional operation being required, into the spin drainer.

With this washing train, brushes, water and shampoo are only used in the area through which the carpet travels. As there are no dead spots, it is possible to achieve significant savings in water and detergent consumption.

The entire process offers a level of cleanness that, until now, has been unattainable by any carpet washing train. Equipped with a water recirculation system.

Then a roller carriage included in the machine is placed in the centrifuge.

There is no vibration transmitted between the spin drainer and the carpet washing train. In model TOTAL 3.5 There can be placed two carpets in the spin drainer as it has 4.5 meters width. The dust remover + the washing train and the spin drainer work at the same time. Therefore, it has a very high productivity.

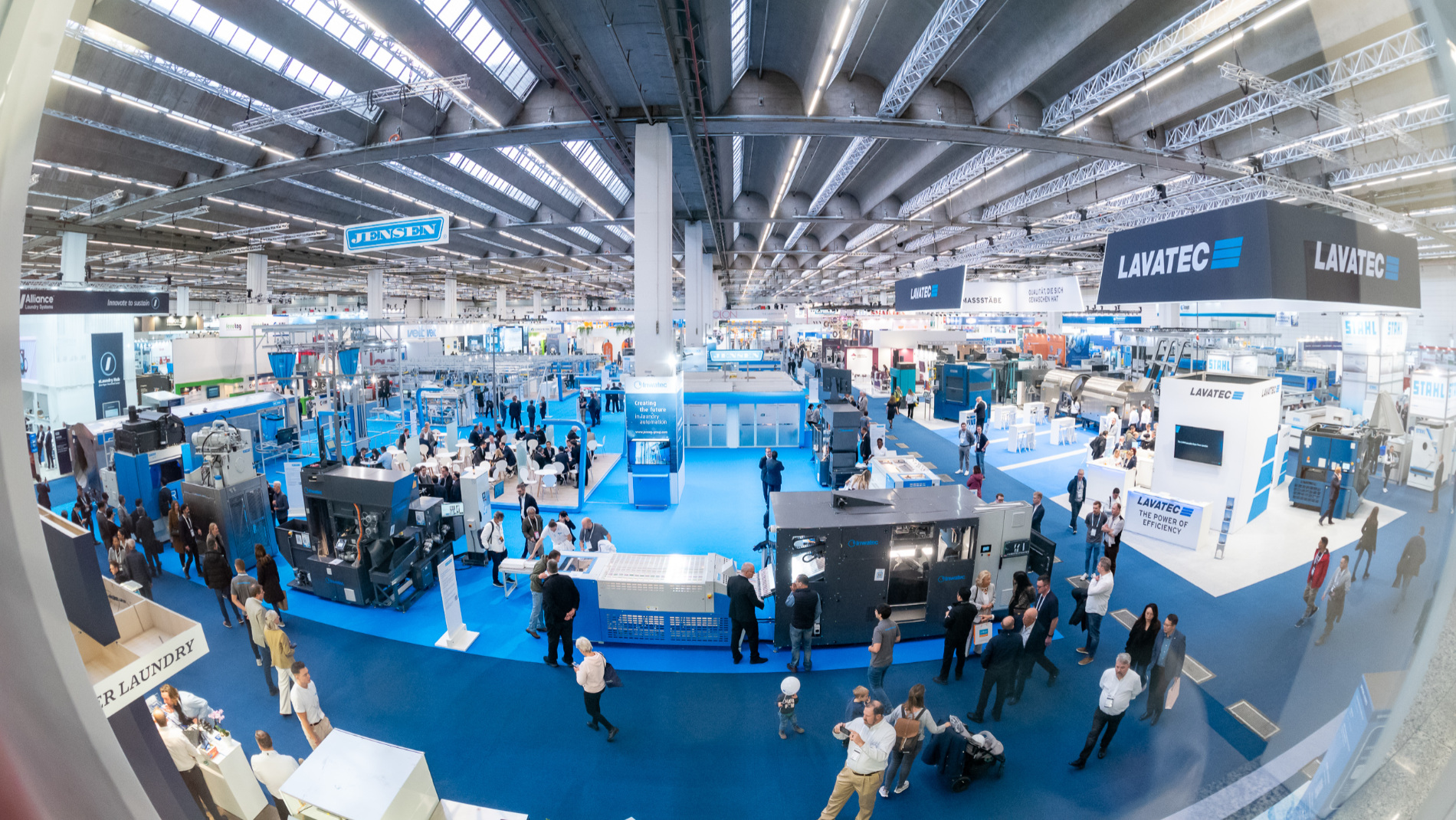

Discover more from us