Reading time: 3 minutes

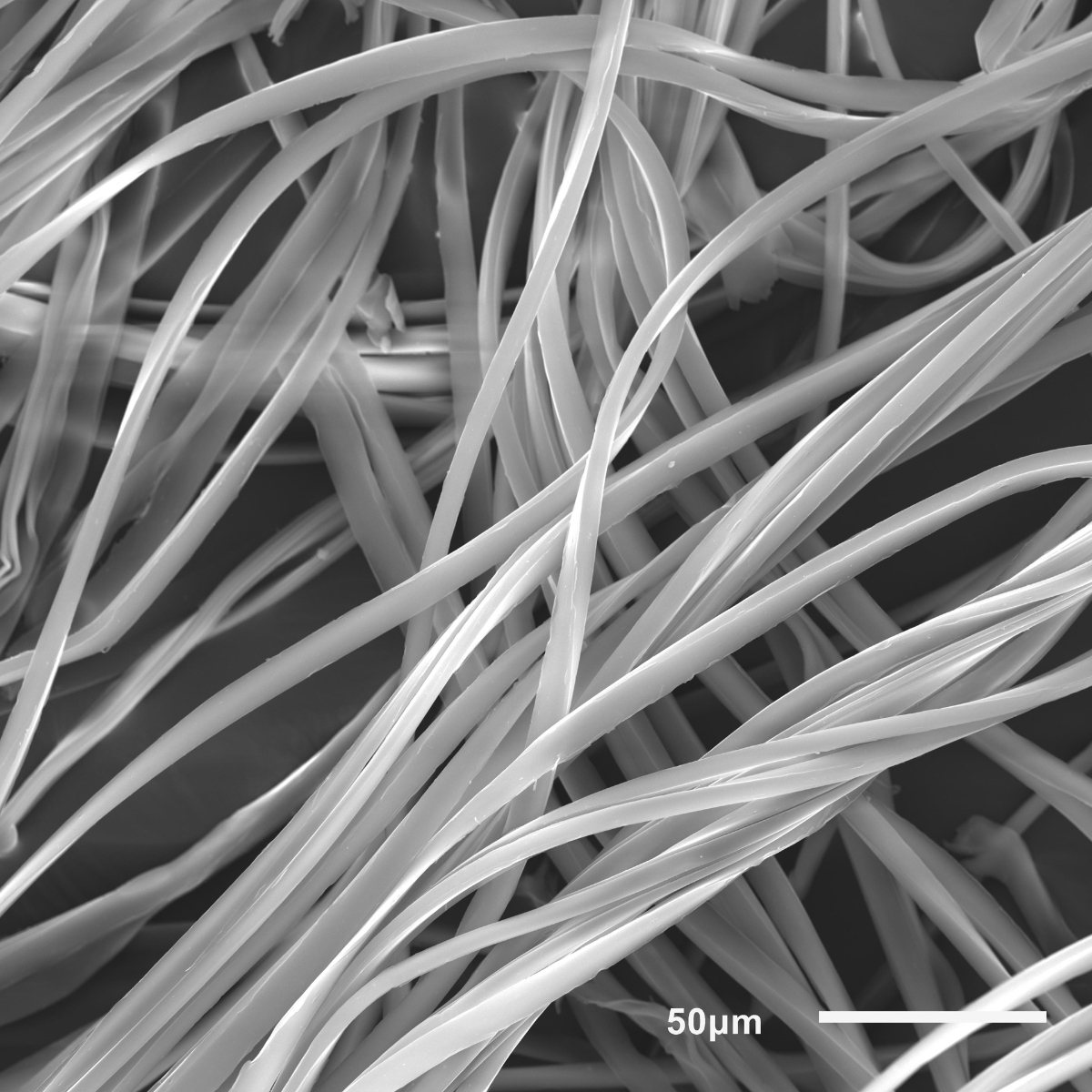

Herbert Sinner is credited with defining the fundamental parameters responsible for cleaning success. Mechanics, time, temperature and chemistry are the key influencing factors for cleanliness. According to his definition, the four factors stand in an exact relationship to each other. However, their magnitude can be adjusted, but they must always add up to the same total. This relationship is illustrated in a circular diagram named after the surfactant chemist: the Sinner’s Circle.

Although the interdependence of the four parameters has been known for many decades, it was often disregarded. How else could the motto “more helps more” in detergent use be explained? If half a scoop of washing powder would have sufficed, a full scoop was often tipped into the machines just to be safe. This practice proved to be uneconomical and unpredictable for operations, problematic for the environment and not conducive to occupational safety.

The development of dosing technology put an end to this. Since then, screw conveyors, diaphragm pumps, Venturi nozzles and the like have ensured the precise addition of powder and liquid detergents as well as chemicals into washing machines and tunnel washers. Thanks to technical advancements, the way of dosing has continuously improved, to the extent that dosing systems have long since developed into small data centres.

Ready to receive: Dosing systems 2.0

The key features of modern dosing technology include – depending on the supplier – powerful hardware combined with internet and cloud connectivity, seamless IoT integration or an app for day-to-day operations. All these systems can be used to set up and adjust dosing programmes and serve to remotely control, monitor and supervise the systems. The digitalisation of dosing therefore brings various advantages for a laundry. Instead of simply relying on the functioning of the dosing system, its work is precisely monitored and documented. This makes it easy to verify, for example, whether the washing substances required for a disinfection programme were added in the correct quantity and at the right time, thereby meeting the requirements for hygienic laundry processing.

Direct control makes dosing safer

Modern dosing systems also put an end to manual interference by unauthorised persons. Adjusting dosing pumps, increasing or reducing quantities is hardly possible anymore, as only authorised persons have access to the programmes and can adapt them if necessary. This gives businesses more security and protects them from unpleasant surprises: processes run according to plan and at the calculated costs.

Online troubleshooting has its limits

Dosing technology 2.0 is also a relief for application technicians of detergent suppliers and system builders. If a customer calls for help because their laundry no longer comes out clean, smells strange or other problems occur, experts can log directly into the dosing system, identify errors or correct them remotely. However, the possibility of remote control, i.e. remote monitoring and steering, is not the ultimate solution. One expert recently summed it up: external access is only a first-aid measure. Root cause analysis and troubleshooting require specialists on site. Only in operation does it become clear what data cannot reveal: the degree and type of soiling in the laundry has changed. The chemical containers have run empty despite level measurement. A dosing line has a leak, a kink or is even blocked. Perhaps the viscosity of an auxiliary agent has been modified since the pump calibration and now affects the preset flow rate. Or the water softening system may not be working properly.

Laundry professionals are irreplaceable

A clean washing result therefore does not only depend on the correct addition of washing substances, but is based on a finely tuned system of various components. One part of this are dosing systems, which provide work relief and process accuracy. But no matter how clever they may be, and how well connected they are with other laundry machines, they cannot replace the expertise of laundry professionals. Their know-how and “view of the bigger picture” are in demand more than ever, despite – or indeed because of – the increasing technologisation of the industry.