Reading time: 4 minutes

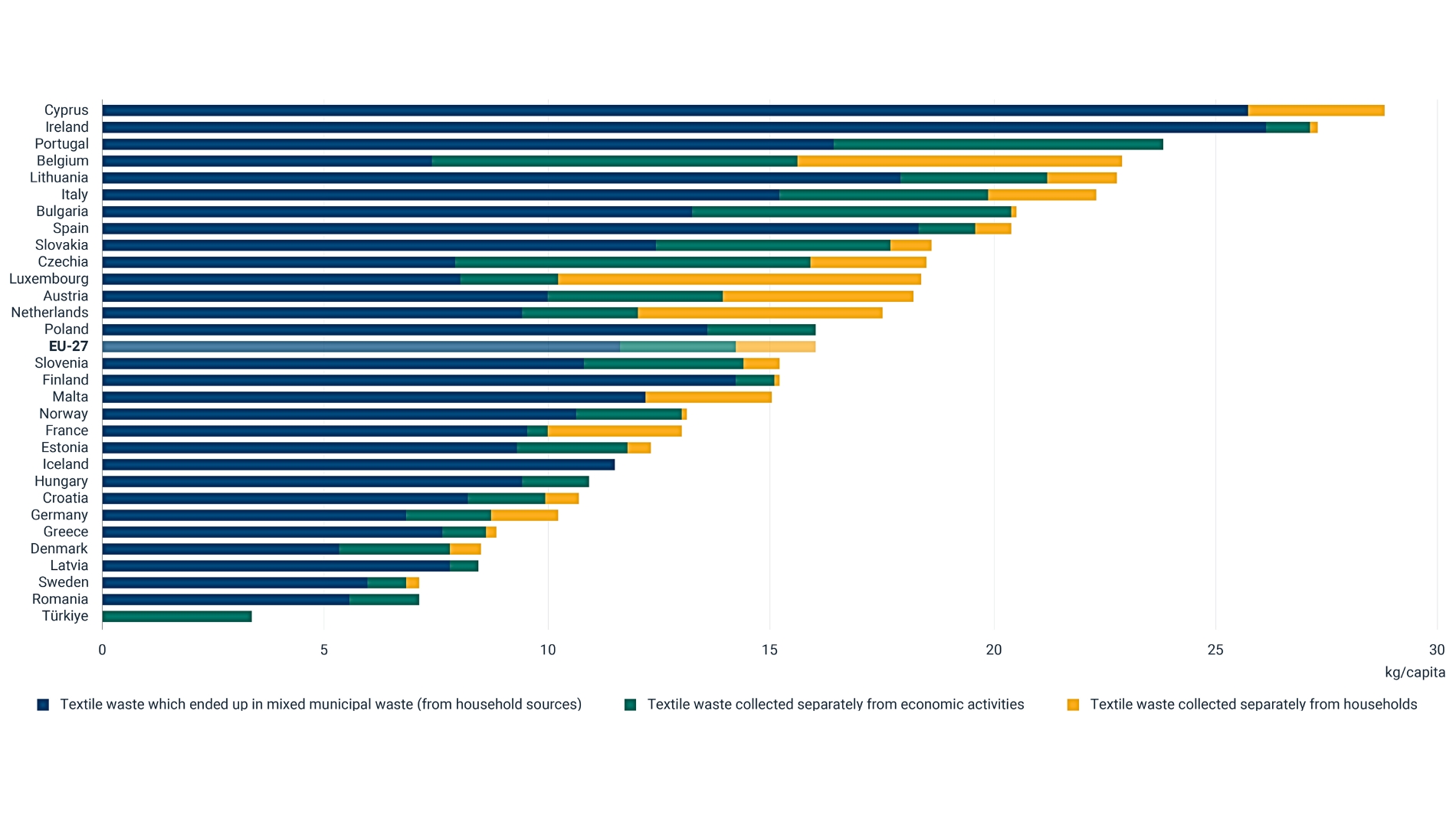

The European Commission has set out to put an end to textile waste and the excessive carbon footprint of the textile and clothing industry. By 2030, all textile products placed on the market in EU member states are to be durable, repairable and recyclable – and largely made from recycled fibres. The aim is to curb the massive flow of textile waste that is discarded across Europe each year. In 2020, this amounted to around 16.5 kg of used textiles and shoes per EU citizen, according to data from the European Environment Agency. Encouragingly, nearly a third of this volume (4.5 kg) was collected via collection containers or through organised household and commercial schemes. Even more promising: a significant proportion of the textiles collected by recycling companies is put to a second use. In this context, the German Textile Recycling Association (FTR) conducted a study on demand, consumption and reuse of clothing. In 2018, 62% of used clothing in Germany was resold as second-hand garments (compared to 67.5% in Italy), 13% was turned into cleaning cloths and insulation materials, 12% was fibre-recycled (in Italy: 25.5%), and 12% was incinerated or disposed of (Italy: 7%).

Textile waste generation in 2020, in kilograms per capita. Source: European Environment Agency

Ultrafast Fashion Undermines Textile Recycling

In Europe, used clothing is already widely treated as a resource and either reused or repurposed. But for policymakers, this isn't enough – the goal is to collect and recycle significantly more. Ironically, it's the very industry that caused the problem that's now standing in the way of a workable implementation of the EU Strategy for Sustainable and Circular Textiles: the flood of ultrafast fashion is damaging the second-hand market and hindering the development of viable mechanical fibre recycling methods. Thomas Fischer, Policy Advisor for Textile Recycling, Circular Economy and Market Development at the German Federal Association for Secondary Raw Materials and Waste Management (bvse, Bonn), and Johannes Leis, Research Associate for Nonwovens and Recycling at the Saxon Textile Research Institute (STFI, Chemnitz), have outlined the challenges that throwaway fashion presents for their work.

bvse |

STFI |

|---|---|

Ultrafast fashion is flooding Europe with clothing at extremely low prices. Second-hand garments, on the other hand, are often more expensive than this new merchandise, as they are usually sorted by hand according to a wide range of criteria by trained specialists. |

Low costs for primary materials create a dilemma in recycling: although secondary products are technically feasible, they are not economically viable compared to new goods. |

The chances of reusing used clothing largely depend on its quality. However, ultrafast fashion is typically of low quality, which makes it much harder to resell as second-hand. |

The quality of collected textiles is declining: an analysis of a post-consumer cotton T-shirt revealed average fibre lengths of less than 12 mm. Fibres this short make mechanical recycling into a closed loop impossible. |

Complex material composites in clothing and packaging are technically challenging and costly to recycle. |

Due to the heterogeneous material composition of used textiles, recycled fibres often exhibit varying fibre properties. This can reduce throughput in subsequent processing steps, increase production waste and drive up costs. |

Implementing the European Textile Strategy will require the development of additional suitable recycling processes and investment in specialised facilities – the approval process for which is often very time-consuming. |

More research and development in textile recycling requires funding. However, the process from submitting a research proposal to receiving approval takes a considerable amount of time. |

Sorted Rental Textiles Offer Ideal Conditions for Recycling

The ever-faster spinning carousel of low-quality budget fashion is a major obstacle to textile recycling. In addition to being unbeatable in price, its poor quality makes reuse as recycled yarns or nonwovens nearly impossible. But there are used textiles that meet the criteria of the recycling industry – namely, discarded rental linen from textile service providers. These items are generated in large quantities directly at the companies’ sites, which makes collection more efficient. What’s more, items such as bed linen, table linen, terry towels, shirts, catering aprons, surgical and cleanroom garments typically have consistent material compositions and colours. They also originate from high-quality primary goods, designed to meet the industry’s demands for durability and leasing suitability. And finally, when they are sorted out of the rental cycle, they’re still clean. The potential of rental textiles has already inspired several recycling initiatives in recent years – both individual and collaborative projects. But just imagine the possibilities if all these efforts were pooled.