Description

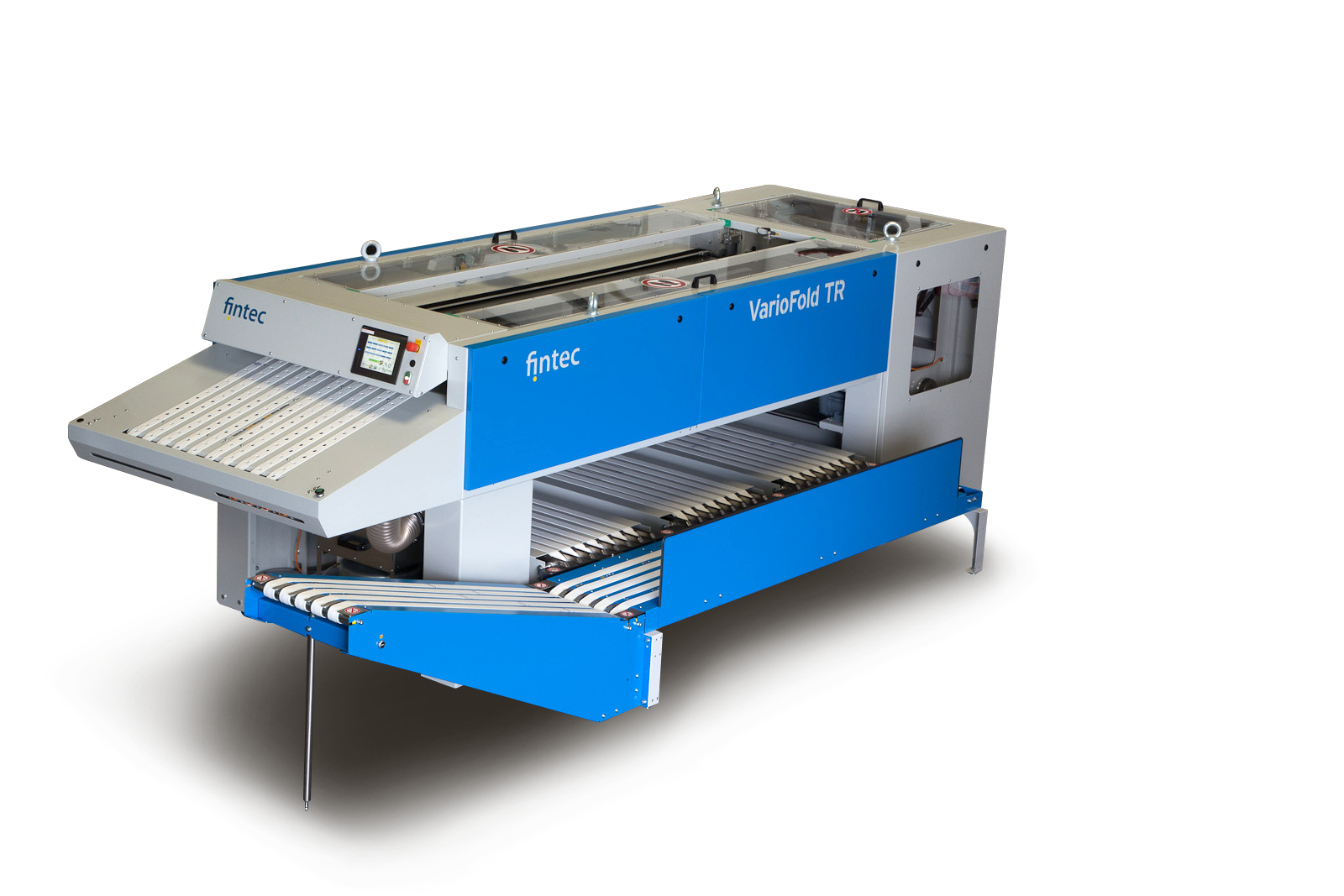

Our high-performance VarioFold F 85 folding robot supports you with excellent and optionally fully automatic processing of molded parts such as work clothing, hospital and resident laundry.

It folds all types of goods with consistent quality. The F 85 M model is manual while the F 85 A is automated. Importantly, these models have a unique Fintec feature: the manual-operation machine version is upgradable fully automated at any time by installing a supplemental module. You don’t have to buy a new machine or modify the machine itself, just connect the attachment needed for pulling out the automated hangers.

The automated model is still usable in manual mode. Switching over is possible at any time to meet your needs, simply by changing the program on the operating terminal. Automated length measurement enables the machine to recognize the differing lengths of top-worn garments. Manually changing programs is not necessary.

You have a clear view into the machine from all sides, and it can be optionally equipped with interior lighting. An optional overalls element is available, enabling complete processing of workwear.

The VarioFold F 85 gives you a wide range of options, as folding and sorting units can be installed in many different configurations, and expanded as required for optimum productivity, based on your laundry capacity. Here too, our modular approach is key.

The machine supports optional sorting according to two criteria, without a separate sorting attachment required. If sorting is to take place according to more than two criteria, a sorting attachment is required, which is optionally available.

After folding, garments can be placed on a variable number of stacking belts. Via an automated process, the folding machine smoothly transfers each item to the sorting attachment connected to the side or rear of the folder.

The machine has a thickness compensation functionality that allows processing of both very thin and very thick laundry items.

If you are already using machines with a common conveyor belt made by another manufacturer, our machines are able to communicate with the existing system, affording seamless integration.

If a laundry item gets stuck, you can use the terminal to control its unloading out of the machine. This is a particularly important function, as it upholds high safety standards. Opening the machine for removal by hand is thus only necessary in exceptional cases.