VarioTrans & VarioLoad

VarioTrans & VarioLoad

Description

VarioTrans transport system and VarioLoad loading stations - your partner from start to finish.

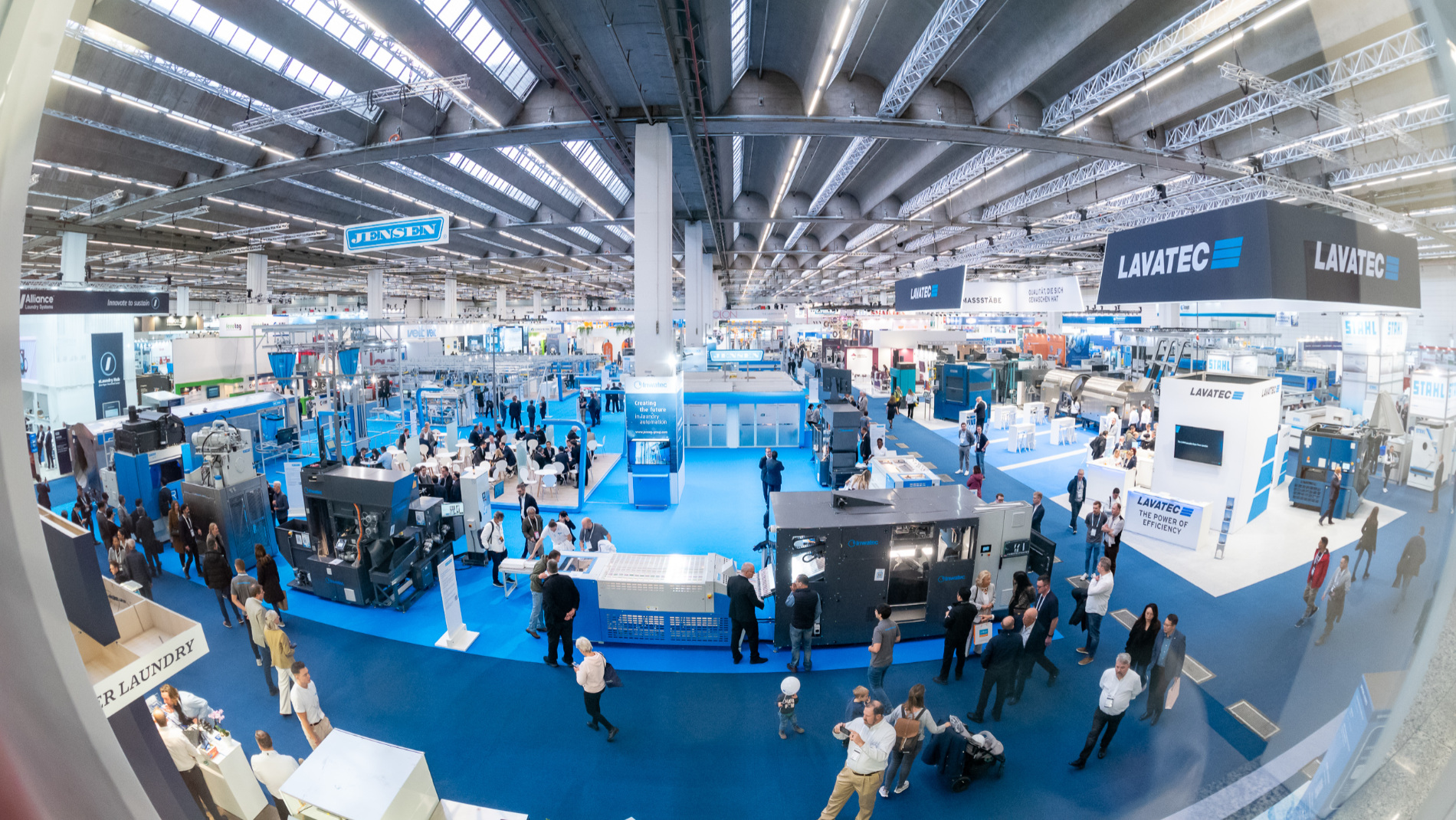

Laundries and textile service providers of all sizes have recognized the benefit of utilizing variable, expandable complete solutions. Fintec offers integratable, adaptable system technology for industry-relevant transport of laundry items. Vario transport technology delivers the logistical performance and reliability our customers demand.

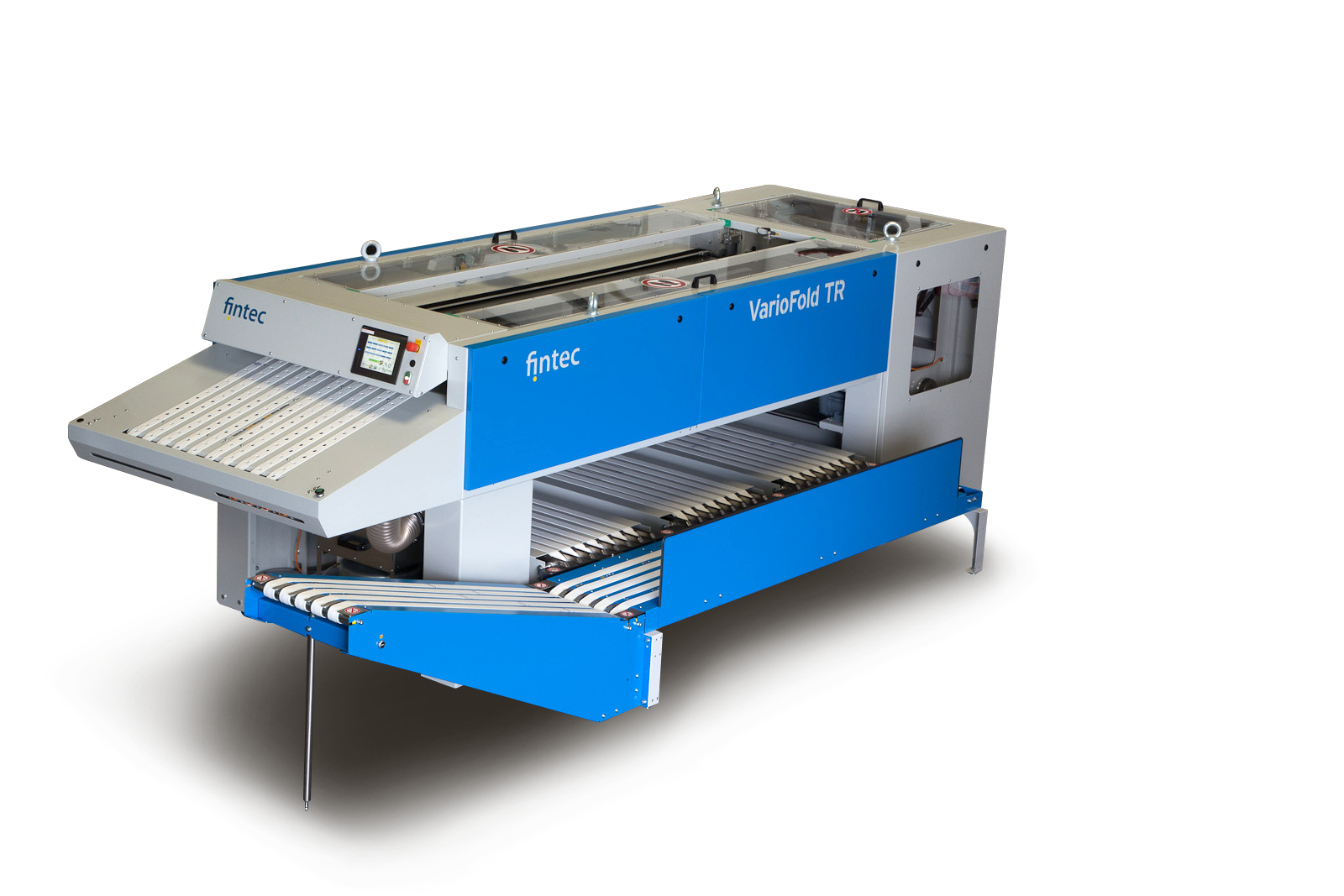

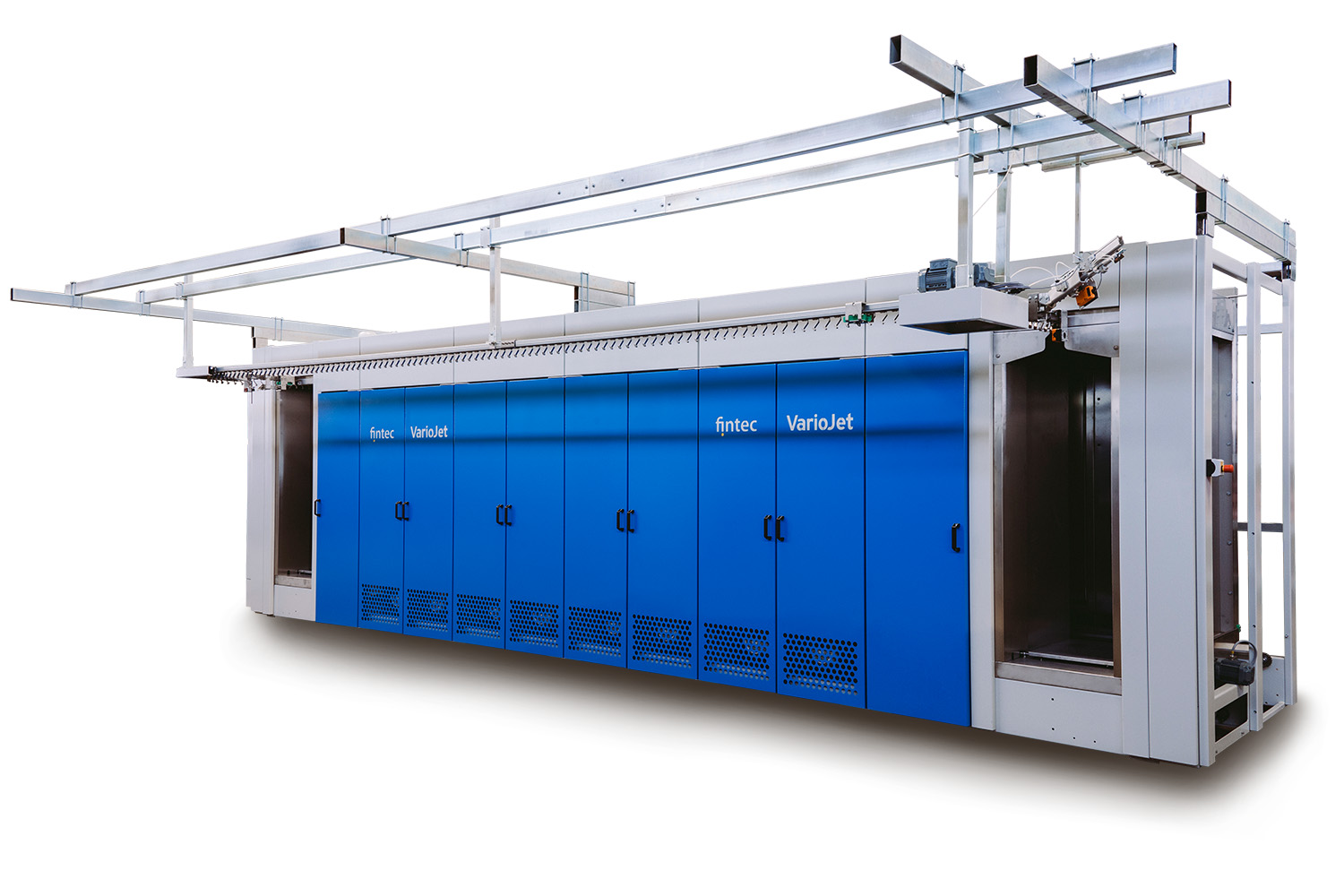

The VarioTrans transport system ensures transport of laundry items from the VarioLoad loading station to the VarioJet tunnel finisher and on to the VarioFold folding machine. The system seamlessly integrates into existing production processes and structures, and is compatible with technical systems of other makes.

Fintec transport systems are customizable to meet your requirements, optionally equippable with accumulation, circular or ascending transports. This flexibility is ideal for a logistically optimal, and thus economical, operational process.

The fully automated, ergonomic VarioLoad loading station is designed for healthier working and continuous productivity. VarioLoad ensures reliable, convenient loading of up to 490 garments per hour. Easy to use from either side, plus stepless-adjusting work height—both important factors!

Empty hangers are fed from a storage magazine in full automation via separator. The infeed start command is executed contactless via photocell; hangers are then transported to the finisher on the ascending transport controlled via frequency converter. The basic VarioLoad E infeed system is an efficient, cost-effective alternative for single-side laundry loading.

Fintec Vario automated hangers ensure optimal garment transport in any system configuration.