Description

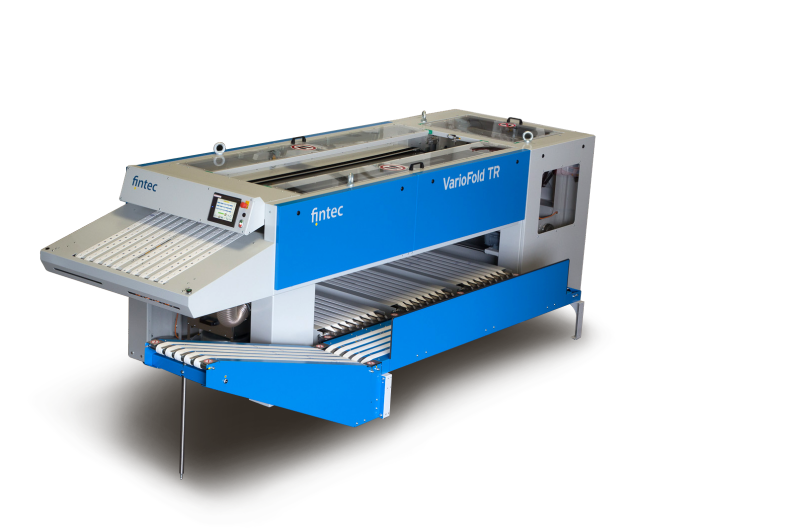

The VarioFold TR 45 takes care of all time-consuming processes of folding, sorting and stacking dry laundry in an array of formats, from bath towels to blankets, from diapers to laundry bags—with no pre-sorting required.

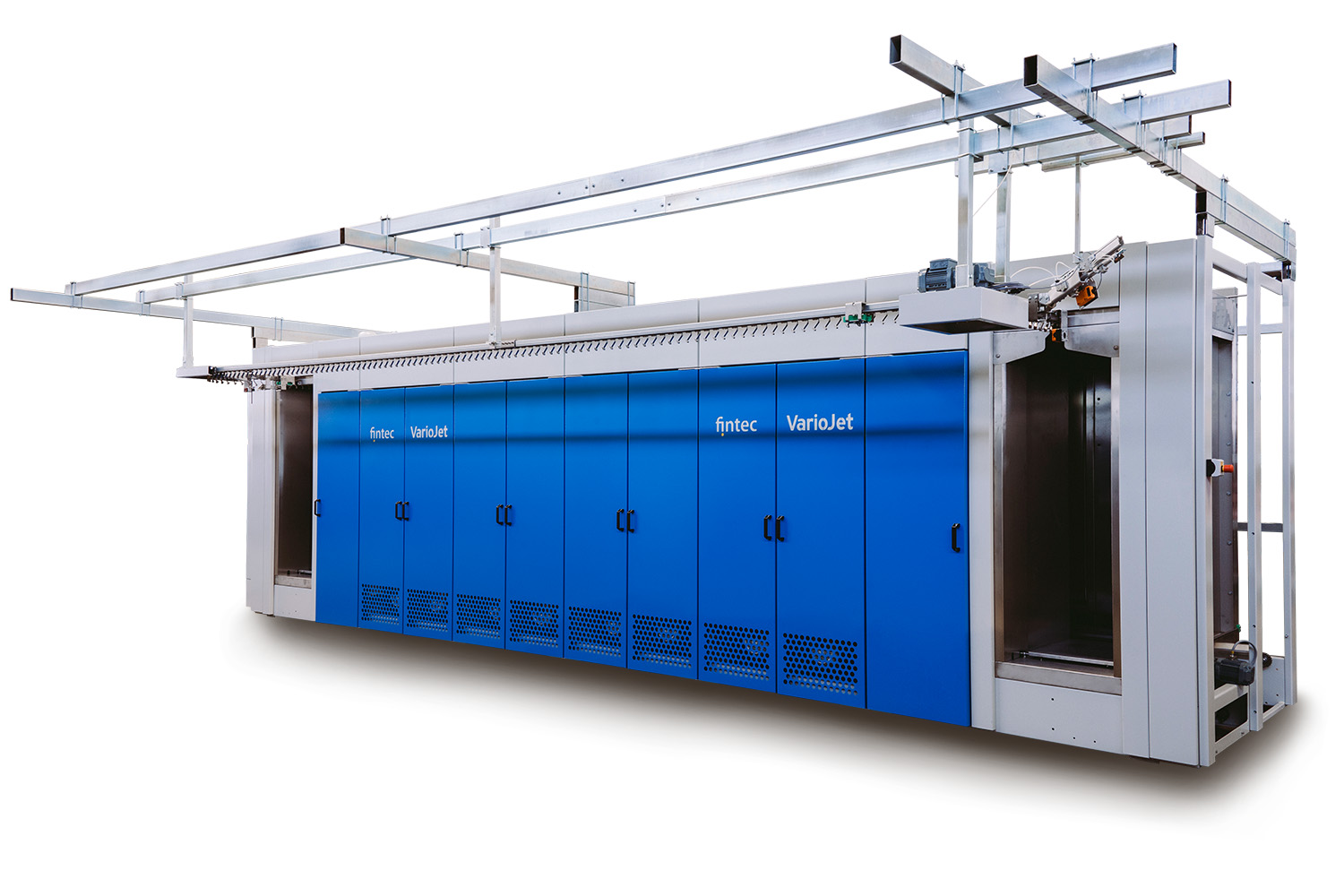

Thanks to the cooperation with robot companies, the garments can now also be fed in automatically - with the help of robots developed especially to take over this task.

The implementation of robot technology in the laundry sector marks a further step towards Industry 4.0. With this innovation and cooperation, we are once again demonstrating why we are one of the leading providers in our field and are always looking for new solutions to optimize processes in laundries.

Our VarioFold TR 45 exclusively works with mechanical blade folding, not with air. The reason for this is simple: air is more expensive, and mechanical ‘blade’ folding affords significantly better quality. The stacked items can be outputted via four individual discharge belts or one single belt. Sliding belts carefully place the laundry stacks on the belt on the long side of the machine.

A fan at the machine inlet sucks in fluff, which is transported off into a box through a tube. The box is located beneath the loading surface; it opens like a drawer for convenient emptying. A transparent pane allowing viewing of the crosswise-folding area is an example of the machine’s user-friendly design.

As the VarioFold F 85, the TR 45 has a thickness compensation functionality that allows processing of both very thin and very thick laundry items. As for the TR 45, this function is beneficial for trouble-free processing of laundry bags with cords and cord stoppers, for example.

If you are already using machines with a common conveyor belt made by another manufacturer, our machines are able to communicate with the existing system, affording seamless integration.

If a laundry item gets stuck, you can use the terminal to control its unloading out of the machine. This is a particularly important function, as it upholds high safety standards. Opening the machine for removal by hand is thus only necessary in exceptional cases.