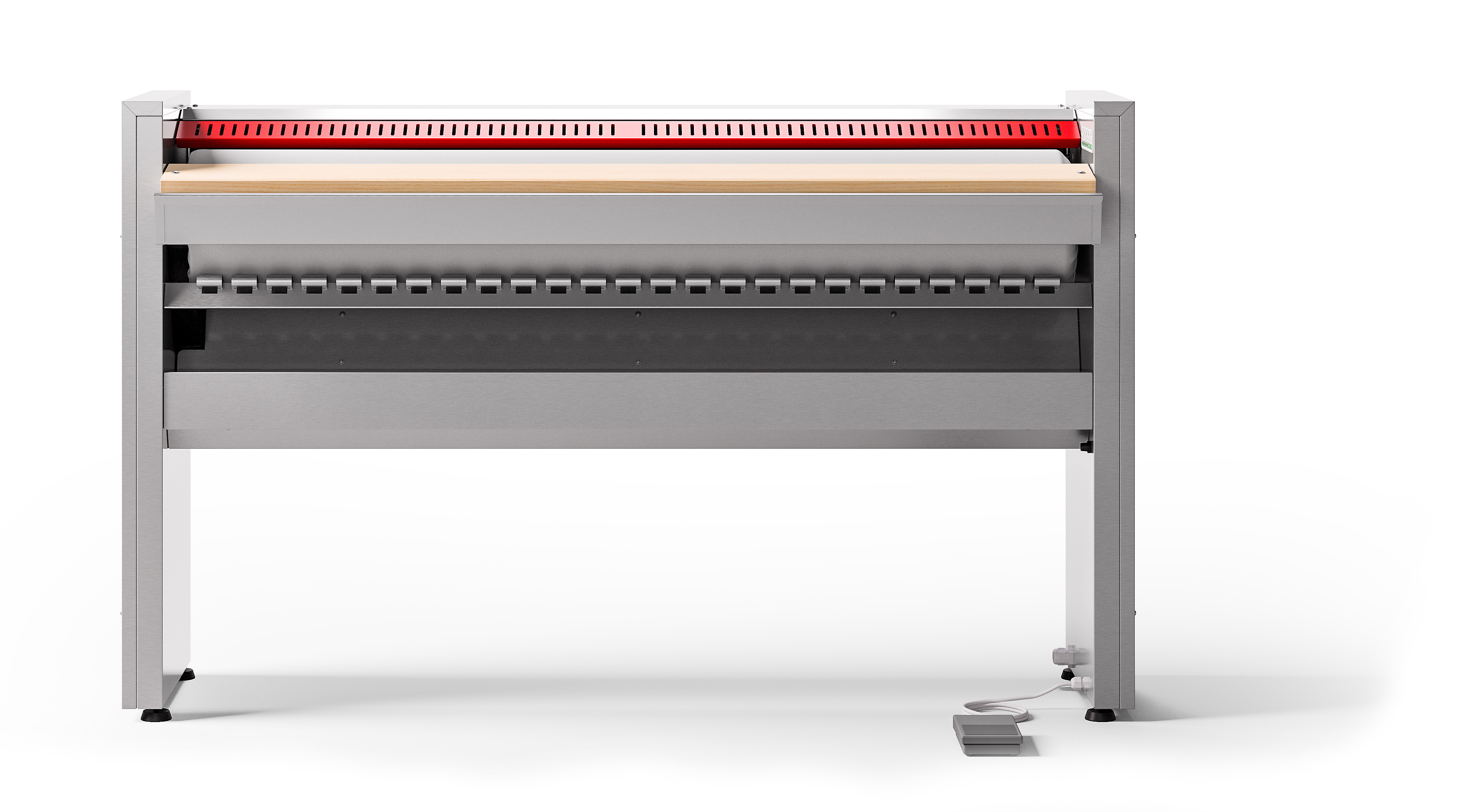

Roller Ironers

Description

GI PROFESSIONAL IRONERS: THE VALUE OF SPACE

Designed around the roller and the basin, the new GI (Grandimpianti Ironers) ironers, with their innovative MCTS (Multipoint Contact Thrust System) and PLS (Pull-wire Lifting System), offer improved ironing results, increased productivity and optimized work space.

The new Multipoint Contact Thrust System (MCTS), by increasing the number of thrust points along the entire length of the ironing basin (with variations in the number depending on the size of the plate) ensures excellent ironing performance in every part of the machine. The presence, then, of a control that adjusts the thrust intensity allows the operator great ironing flexibility.

The ability to adjust temperature, roller rotation speed, and plate thrust ensures,

not only excellent ironing quality, but also great versatility of use, reliability of performance over time, and uniformity in the life of the entire machine.

TEMPERATURE UNDER CONTROL

The heating elements are placed inside the ironing plate (heat is generated from the center) and arranged asymmetrically: 66% of the heat is concentrated in the initial part, where the plate undergoes the greatest thermal shock (the laundry is cold and wet), and the remaining 33% at the exit of the laundry. This ensures temperature uniformity over the entire surface ensuring outstanding performance.

ERGONOMICS & PRACTICALITY

Every detail of the new GI ironers is designed to provide the most comfortable working position for the operator. Such as the innovative Adjustable Infeed Plate (AIP), the wooden linen introduction board, which can be adjusted to various angles, preventing overheating and any electrostatic charge as well as ensuring maximum comfort.

SECURITY

Excellent performance requires maximum reliability and safety, which is why we have developed the new Automatic Thermal Protection System (ATPS) that can automatically move the ironing basin away from the garments in the event of a breakdown or power failure. GI ironers, moreover, are equipped with a finger-guard band cooling system, Finger-guard Cooling System (FCS), and 2 temperature sensors that, in case of overheating detected by the electronic board, takes action by turning off the heating system. A dual heating activation system, then, with two contactors, ensures that in case of failure the machine is always safe.

SERIES WITH FOX CONTROL

- Turning on and off

- Side display with push button panel

- Live program customization (no memorization)

- Roller speed adjustment (4 levels

- )Adjusting the thrust of the basin

- Temperature regulation

Address

Grandimpianti I.L.E. ALI Group S.r.l. a Socio Unico

Via G. e A. Trevisson 5

32037 Sospirolo Belluno

Italy

Telephone+39 0437 848711

Fax+39 0437 879108

Discover more from us