Reading time: 4 minutes

Large parts of the hospitality and healthcare sectors rely on white bed, table and terry linen. These textiles are universally applicable and suit almost any interior style. They also convey a sense of hygiene, cleanliness and professionalism. To maintain this effect despite frequent reprocessing, detergents containing optical brighteners are used. They create the bright white appearance desired by hotels, hospitals and care facilities. However, growing ecological awareness is prompting some laundries to rethink their approach and abandon brighteners. Andreas Janning, Deputy Managing Director of Gütegemeinschaft sachgemäße Wäschepflege (Bönnigheim) and trained textile care master, explains further.

What is the purpose of optical brighteners in textile care?

Optical brighteners (also known as fluorescent whitening agents) are special dyes designed to make textiles appear whiter, brighter and fresher. They are structured in such a way that they convert invisible UV light into visible blue-violet light, neutralising the yellowish tinge of repeatedly washed textiles and making the material appear optically “whiter”.

New textiles are already dyed with optical brighteners and often carry a residual surface surplus. Is the whiteness of new fabrics not sufficient to achieve the desired result?

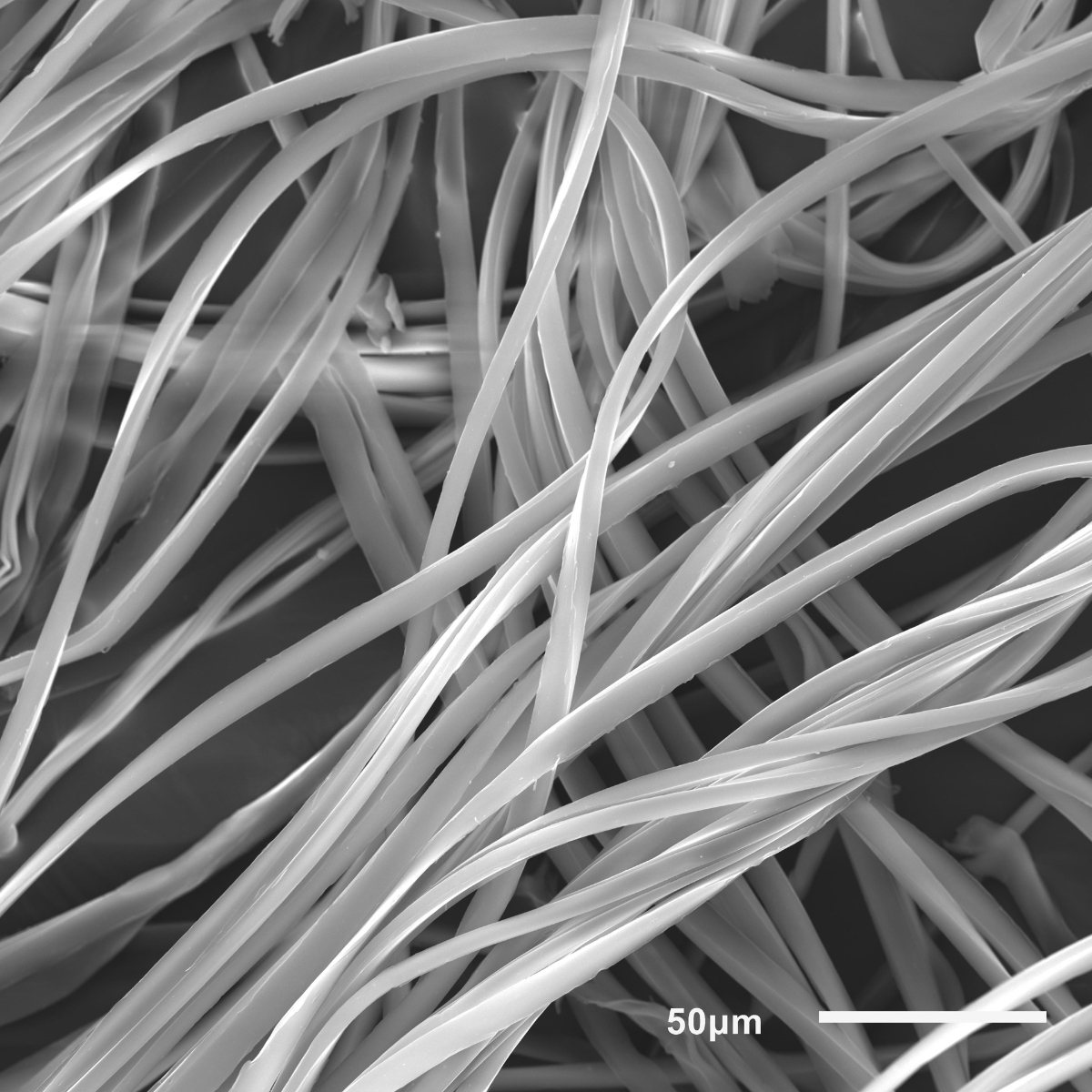

In professional textiles, optical brighteners are already added to synthetic fibres during the spinning process. This permanent incorporation ensures that the fibres maintain a high degree of whiteness – without relying on washing processes. Nevertheless, this effect fades over time, which makes a subsequent refresh through detergent additives worthwhile. Cotton is also dyed “white”, meaning that the initial whiteness of blended fabrics is sufficient. Yet textiles gradually yellow due to mechanical stress, heat, cleaning chemicals and, above all, fibre ageing. Optical brighteners counteract this effect by “refreshing” the degree of whiteness optically.

Can whiteness be maintained without the use of optical brighteners in the laundry process?

There are several alternative methods to preserve or enhance whiteness. These include the addition of bleaching agents (e.g. oxygen-based) in the main wash, special washing procedures (such as enzymatic cleaning) or the traditional method of bluing, practised until the 20th century. Bluing involved a colour correction with bluish laundry aids (“blue paper”, “blueing”) or the addition of blue dyes. However, such methods cannot match the brilliance and uniform effect of optical brighteners, which I consider to be a gentle and effective supplement in the commercial sector, especially for repeatedly washed textiles. Chemical bleaching is also a harsher process that stresses the fibres more and leads to faster wear of the textiles.

Blue, red, green – brighteners come with different shades. Do countries have varying preferences for the “tint” of whiteness?

Yes, there are indeed regional preferences when it comes to optical effects. In Europe and North America, a neutral to bluish white tone is favoured, as it conveys a sense of freshness and hygiene. In Asian countries such as China, South Korea or Japan, a more reddish or greenish tone of white is perceived as “purer” or “more luxurious”. In parts of Africa and the Middle East, the specific tone is less important; instead, the general brilliance of the fabric is decisive. Due to these different regional preferences and aesthetic expectations, the detergent industry develops products tailored to each market.

How much optical brightener is used in industrial laundry?

The amounts applied in professional laundries are very small, typically ranging from 0.01–0.05% relative to textile weight. Despite such low quantities, the effect is very visible thanks to the strong fluorescence. This meets the expectations of textile service customers, for whom both textile quality and appearance are crucial: hotels, hospitals, nursing homes or airlines all evaluate textiles visually – and a brilliantly white sheet or towel consistently leaves a positive impression of cleanliness, hygiene and care.