Reading time: 3 minutes

The global textile care industry appears unable to do without optical brighteners. However, these substances are chemically stable and only slowly biodegradable. With growing ecological awareness in the textile care sector, the use of such dyes raises important questions. Answers are provided by Andreas Janning, Deputy Managing Director of Gütegemeinschaft sachgemäße Wäschepflege (Bönnigheim).

Can laundries really not do without optical brighteners when processing white bed, table and terry linen?

Andreas Janning: A complete renunciation of optical brighteners in commercial laundries is rather rare, as demand for a “brilliant white” remains consistently high in many sectors. However, there are trends towards more conscious use: in Scandinavia (e.g. Sweden, Norway), greater emphasis is placed on sustainable washing processes. Here, the use of optical brighteners is reduced or replaced by products certified under the EU Ecolabel, which prohibits the use of optical brighteners in detergents. In Germany, Austria and Switzerland, some laundries switch to less fluorescent products as part of EMAS or ISO 14001 certifications. In addition, certain hotels and hospitals with an ecological orientation do without brighteners altogether.

When switching to a brightener-free detergent, what needs to be considered?

Andreas Janning: Optical brighteners introduced via textiles and detergents can accumulate in washing machines and then be transferred to subsequent wash loads. Even if a textile care company is already working with a brightener-free process, the carry-over of these fluorescent dyes can still produce a brightening effect on textiles for some time. A process change therefore cannot happen overnight; it takes time until the brighteners are completely removed from the machines.

One advantage of brightener-free processes is that this class of dyes no longer enters the wastewater. From an environmental point of view, this is good news, since optical brighteners are chemically stable and only slowly biodegradable.

Andreas Janning: In fact, these fluorescent dyes can only be partially removed in conventional biological treatment stages and may therefore enter surface waters. There, they can disrupt the natural UV-light balance – with potential effects on microorganisms and aquatic life. Some optical brighteners can also accumulate in sewage sludge, which may cause problems if the sludge is later used as fertiliser.

How can the side effects of optical brighteners in a wastewater treatment plant be minimised?

Andreas Janning: In the EU, strict limits and approvals apply, meaning that only certified and relatively environmentally compatible brighteners may be used. More eco-friendly brighteners (e.g. based on stilbene derivatives) are now widely standard. However, it must be borne in mind that ecological risks depend heavily on product choice, dosage and the disposal system.

In many developing countries, cost and availability are decisive – less attention is paid to the targeted use of brighteners, even though the ecological impact may be greater due to a lack of wastewater treatment facilities.

And how can the presence of optical brighteners affect a laundry’s process water treatment?

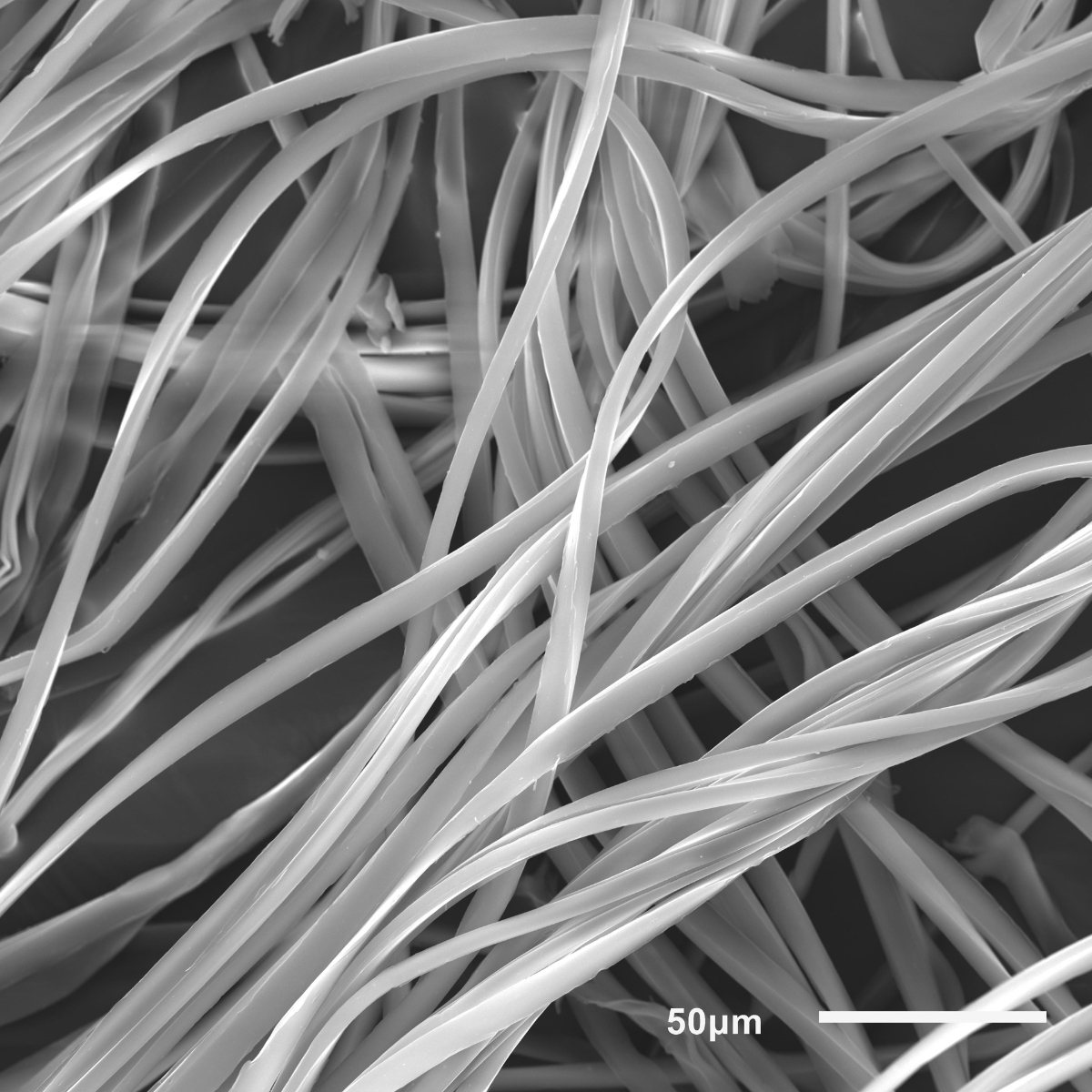

Andreas Janning: The concentration of optical brighteners in the effluent of an industrial laundry is usually very low, which means they can largely be retained by modern membrane filtration systems. However, water recovery systems installed, for example those based on reverse osmosis or nanofiltration, can experience deposits of optical brighteners on the membranes. This may lead to increased maintenance requirements. Therefore, precise dosing of brighteners in the washing process and reliable system monitoring are essential.

And this, in fact, seems to be the art of professional textile care: by using low-residue products, applying them sustainably and dosing responsibly, ecological risks can be minimised.