Reading time: 4 minutes

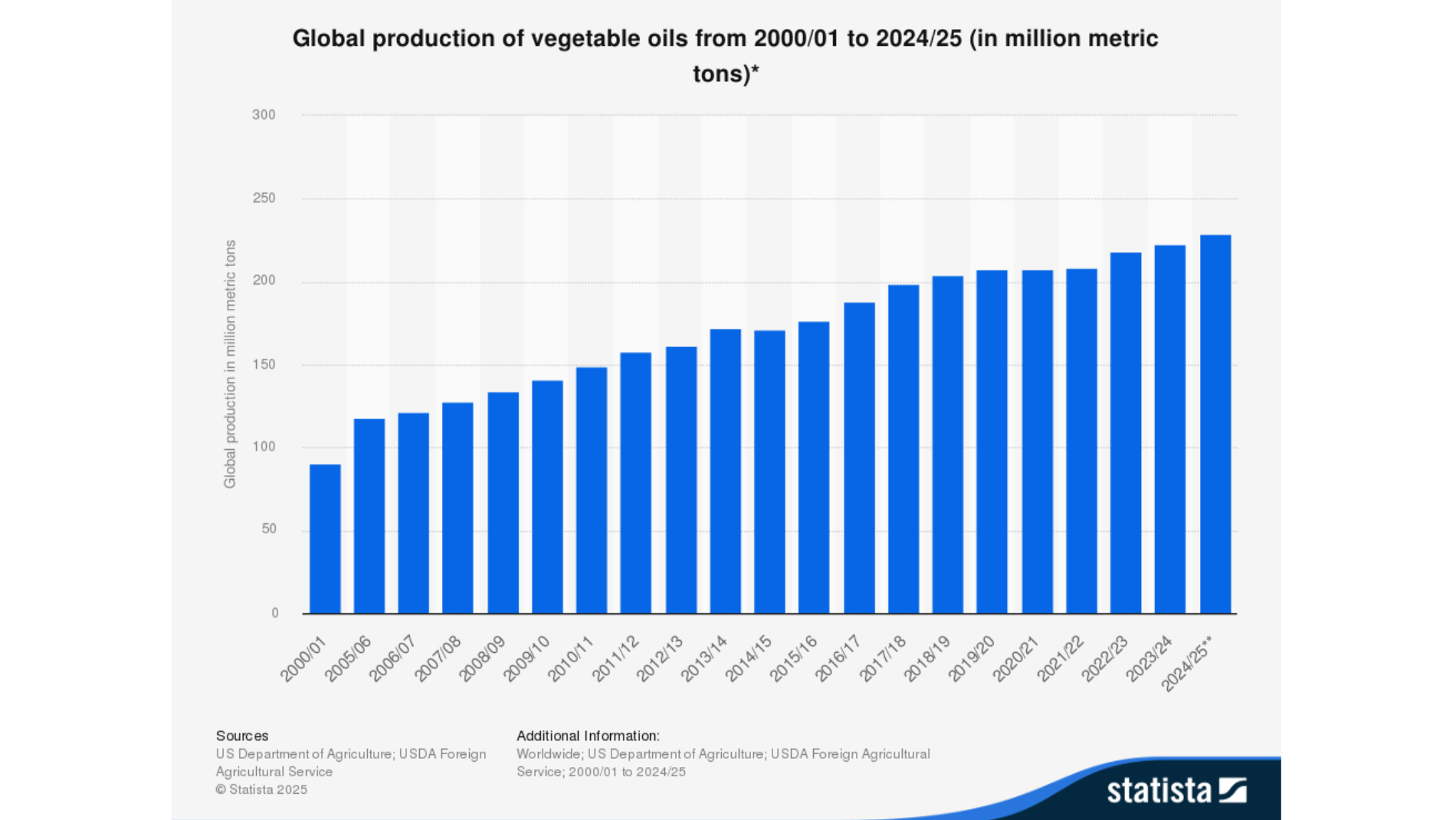

According to the European Commission, 27 member states are to become climate-neutral by 2050. This decision requires a cross-industry shift from fossil to renewable and recycled resources. In energy generation, this transition is already well under way: electricity is increasingly being produced from renewable sources. In the chemical industry, however, the replacement of fossil raw materials is progressing at a much slower pace. Many products – including the high-performance detergents indispensable for industrial laundry – are still largely based on petroleum. Owing to their lower carbon footprint, palm and palm kernel oil, sunflower, soya, coconut and rapeseed oil have long been used in surfactant synthesis. Yet these alternative raw materials also bring with them a number of challenges.

Challenges of Bio-Oils in Surfactant Synthesis

- Availability: The quantity of plant-based oils and the surfactants derived from them is limited; the availability of petroleum-based surfactants is significantly higher.

- Effectiveness: The efficiency of surfactants synthesised from natural oils varies. Surfactants derived from rapeseed oil, for example, are less effective than those based on petroleum.

- Variety: The range of surfactants produced from renewable raw materials is limited, which is reflected in higher price levels. One of the most productive natural products is palm kernel oil, extracted from the fruit of the oil palm.

- Price: Surfactants obtained from natural raw materials are more expensive than those derived from petroleum. This drives up the cost of industrial detergents, which, according to manufacturers, is not accepted by customers.

- Competition between material and nutritional use: Soya, coconut and sunflower oil are essential raw materials for the food and feed industries, both directly and indirectly. Their additional industrial use – beyond biofuels – removes them from the global food chain, raising ethical concerns.

- Cultivation: Palm oil has a very favourable yield-to-land ratio. However, oil palm cultivation is linked to social grievances on plantations, human rights violations, groundwater depletion, land conflicts, deforestation (including rainforests), the destruction of natural habitats and biodiversity loss. To mitigate negative impacts, the chemical industry – which produces surfactants from palm kernel oil – has joined the Round Table on Sustainable Palm Oil (RSPO). This non-profit organisation advocates for a more sustainable palm oil industry. RSPO-certified palm oil can be sourced through four supply chain models: identity preserved, segregated, mass balance, and RSPO credits / book & claim. For surfactant production, mass balance palm oil is most commonly used, whereby certified sustainable palm oil is mixed with conventional palm oil during the supply chain.

- EU Deforestation Regulation: EU Regulation 2023/1115 on deforestation-free products aims to protect forests worldwide from clearance for agricultural raw materials. Its scope includes soya and oil palm, as well as products derived from them. From 30 December 2025, medium and large companies will be required to provide extensive documentation and proof of origin for these raw materials.

Biobased Professional Detergent Range – on the Market for Years

Despite the many pitfalls associated with producing biobased surfactants, Steinfels Swiss (Winterthur) has successfully navigated all obstacles and developed a product line made entirely from natural raw materials: MayaTex. The range includes various liquid detergents and washing auxiliaries designed for industrial textile care operations, ensuring environmentally friendly and hygienic laundry processing. However, according to Irene Wirz, Head of Development at Steinfels Swiss, the real lever for sustainable textile care lies elsewhere: “The goal must be to reduce surfactant consumption in the laundry sector. By optimally adjusting the dosage of all washing substances to suit the level of soiling, load size and type of material, the greatest environmental benefits can still be achieved.”

Washing Substances Account for >10% of a Laundry’s Carbon Footprint

This argument gains further weight when looking at the carbon footprint of a textile care company: “For Greif Mietwäsche, we calculated the Corporate Carbon Footprint across Scope 1, 2 and 3 emissions. Within Scope 3’s ‘Purchased Goods & Services’, emissions account for 26%. This includes all detergents and auxiliaries, purchased textiles, stainless steel containers and more. If we combine the share of surfactants from petrochemicals with all purchased chemicals, the result is 38% of our Scope 3 emissions. This gives them a significant impact on our climate balance, contributing around 10% of our total emissions,” explains Darvin Nowak, Head of CSR at Greif Mietwäsche (Augsburg). However, he points out that the impact of washing substances and surfactants on a company’s CO₂ emissions always depends on the products used. For example, when hypochlorite processes are applied, the percentage can rise. “In such cases, the share could be as high as 14 to 15%,” Nowak estimates.

Secondary Raw Materials from Construction to Be Used in Detergents

In order to reduce the environmental impact of detergents, manufacturer Christeyns (Ghent) is committed to recycling residual materials as feedstock for its products. Several years ago, the company launched the Coffee Soap project, which aimed to produce soap from used coffee grounds. Due to excessive contamination in the raw material, the initiative was discontinued. Since then, Christeyns has taken a different approach to lowering its environmental footprint: “We are a partner in the EU-funded HORIZON project FIC-FIGHTERS. Essentially, it focuses on recycling phosphogypsum waste into commercial products through sustainable, circular processes. This allows us to extract two essential detergent components from the residual material: sodium sulphate, which serves as a filler in our powder products, and ammonium sulphate, which is used in neutralisation,” explains Dr Stefan Vautrin, Product Manager at Christeyns.

Fungi and Bacteria as New Surfactant Raw Materials?

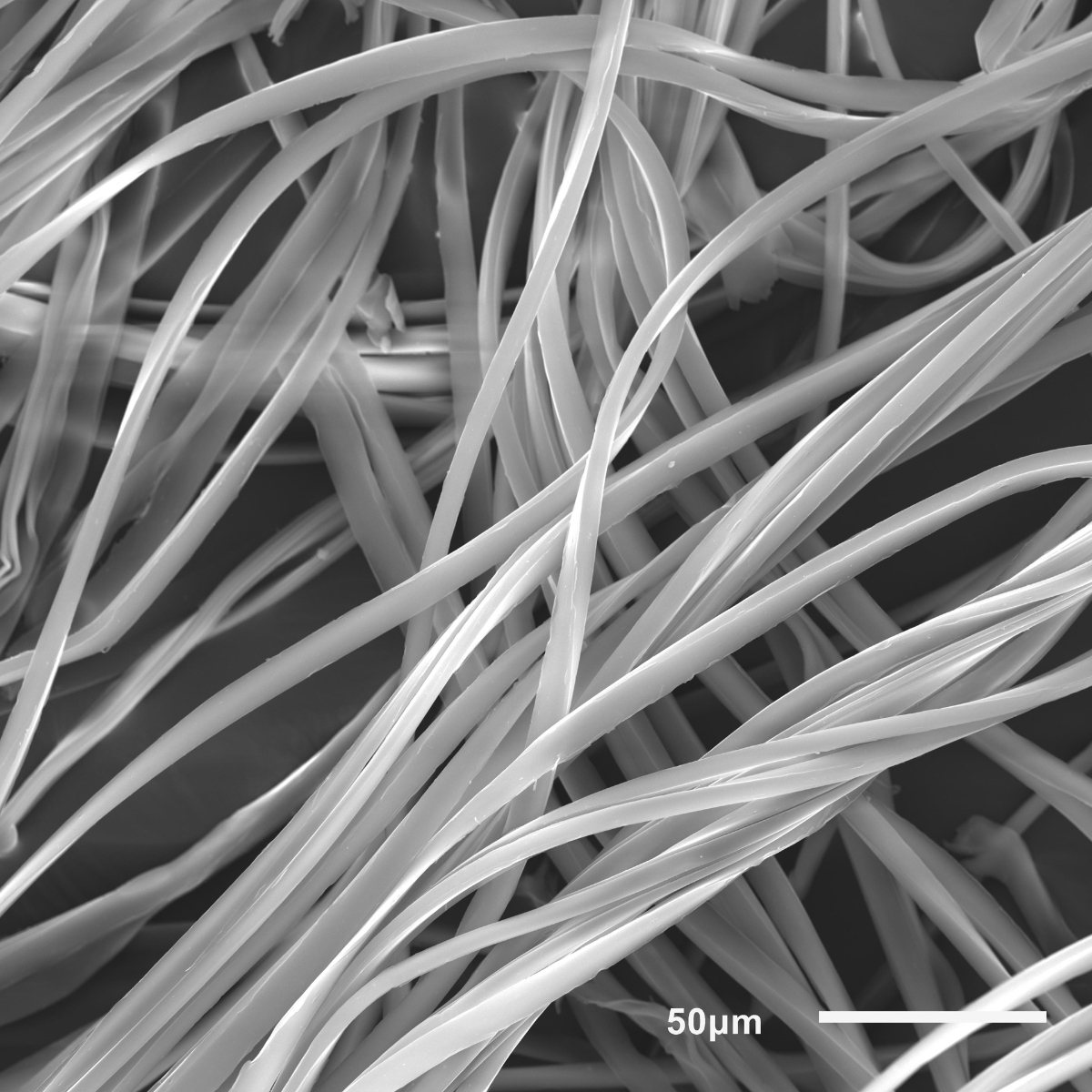

In the search for alternative raw materials, not only biogenic waste and secondary resources may prove valuable. The chemical industry and research institutions are already exploring other sources. For instance, the Fraunhofer Institute for Interfacial Engineering and Biotechnology is investigating surfactants that are microbially produced by fungi and bacteria. Such processes could offer a major advantage: instead of chemical synthesis, detergents could be produced in fermenters – with significantly lower carbon dioxide emissions.