Reading time: 4 minutes

In the textile care sector, conserving resources, reducing emissions and preserving textile performance are top priorities. Achieving these goals requires more than modern machinery, advanced recovery systems and optimised logistics. What’s also needed is highly effective chemistry that supports minimal product use while delivering maximum cleaning performance. To balance ecological and economic demands, detergents must enable unrestricted water recycling, avoid increasing the pollutant load in wastewater and, ideally, not contribute to a laundry’s Scope 3 emissions. Solvents, in turn, should be environmentally friendly – certified where possible – and ideally biodegradable, or replaced altogether by water- or CO₂-based processes wherever feasible.

Lemon Oil and Sugar Cane – Washing and Cleaning with Renewable Raw Materials

Although the principles of sustainability have not yet been fully applied to washing and cleaning processes, various developments in detergents and chemicals offer reason for optimism. It starts with the formulation itself: some surfactants and solvents are already synthesised from renewable raw materials such as plant-based oils (e.g. coconut, rapeseed or citrus peel oils), corn, sugar cane or even cellulose – or at least contain a proportion of these ingredients. Using such natural base materials has a positive impact on the carbon footprint of detergents and the Scope 3 emissions of laundries. They can also improve biodegradability, which in turn helps reduce the environmental impact of wastewater.

Less Is Sometimes More – Especially for the Environment

The concentration of detergents is a welcome development for the environment. Instead of shipping water-based surfactants, concentrated active ingredients are delivered, reducing transport volumes. Another ecological improvement is the modular structure of detergent systems: rather than using all-in-one formulations, only the surfactants required for the specific degree of soiling and fabric type are applied. Optical brighteners have also become optional – a development that originated in environmentally conscious Scandinavia, where many laundries forego them, as whiteness is already present in table linen, towels and bed linen. To ensure that sustainable chemistry is more than just a marketing claim, detergents and cleaning agents are increasingly certified according to recognised standards such as the EU Ecolabel or the Global Organic Textile Standard (GOTS).

Water and Solvents Both Have Their Place in Textile Cleaning

With growing environmental awareness among textile care providers and consumers, a long-established cleaning method is experiencing a revival: wet cleaning, which has been awarded the Blue Angel ecolabel. Originally developed for delicate and sensitive materials, this method relies on the most environmentally friendly “solvent” available – water. It is safe for both health and the environment, and it can remove stains that traditional solvents often fail to tackle – including sweat, beverages, sugar and dust. However, for greasy or oily soiling, and for garments bearing a care label with a crossed-out “W”, chemical cleaning still plays an important role. As it also helps extend the life of textiles, it contributes in its own way to environmental sustainability.

Balancing the Sinner’s Circle

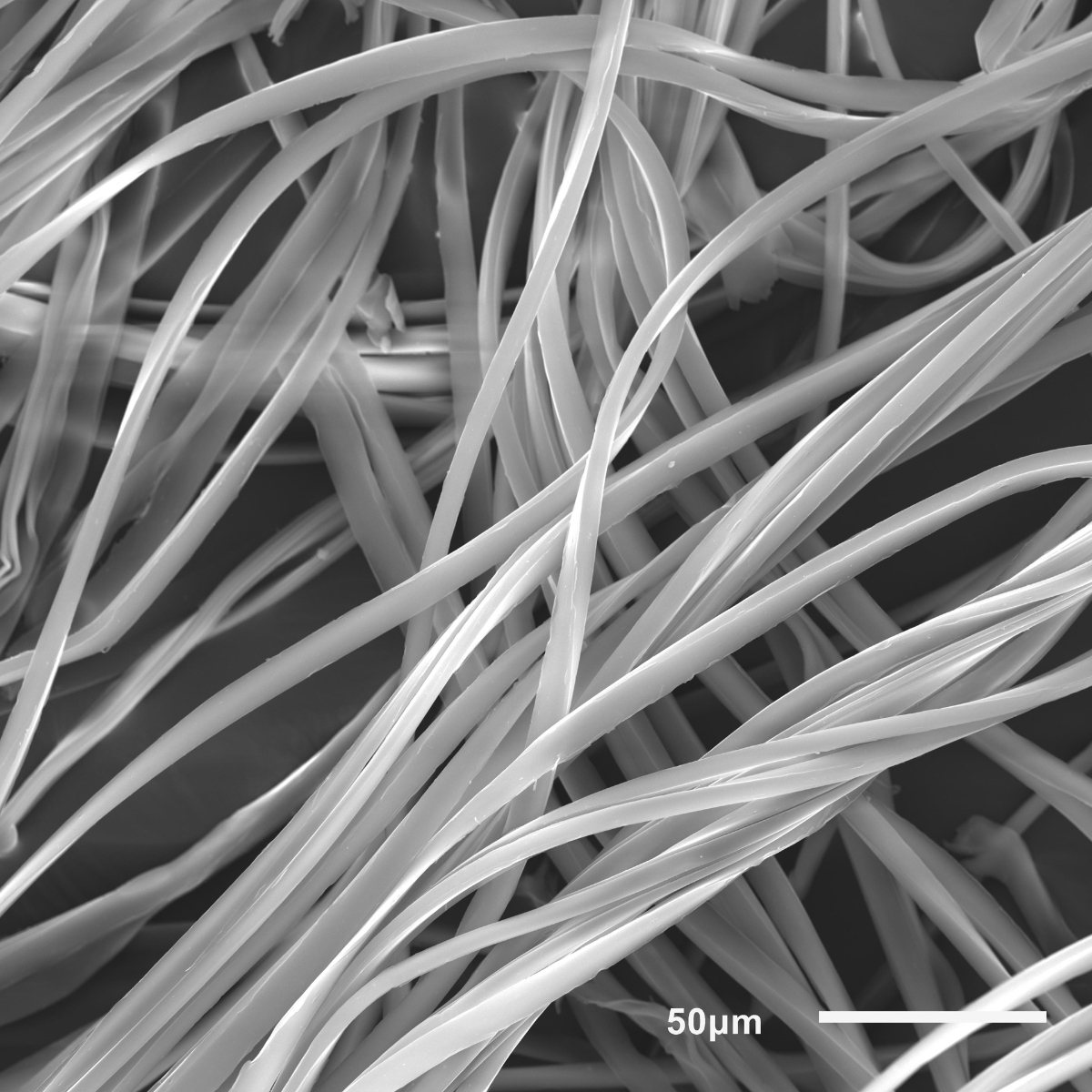

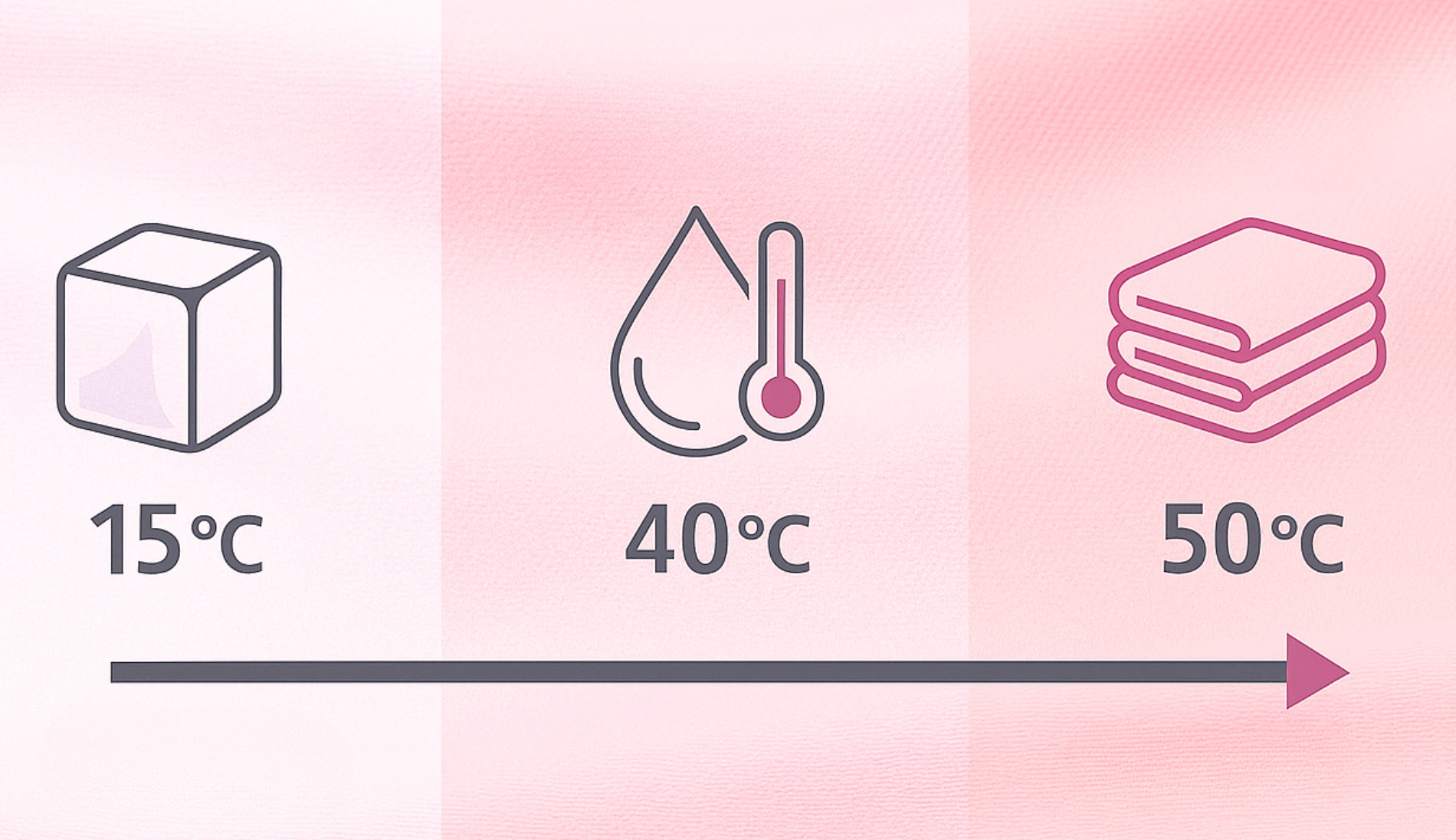

One of the most significant factors influencing resource consumption and carbon footprint in textile care is the temperature range a detergent is designed for. Until recently, the motto was “less is more”: disinfecting agents were expected to eliminate microorganisms at just 40 °C, and even cold washing processes were explored in an effort to reduce the energy needed to heat wash water. But this approach has its limits. Many laundries now use advanced heat recovery systems to preheat water, but the Sinner’s Circle has once again proven its relevance. Lower washing temperatures inevitably increase the need for more potent chemical action, since water levels and mechanical action in machines are essentially fixed. The consequences soon became clear: stronger detergents damaged textile fibres, reducing the lifespan of workwear, hotel linen and healthcare textiles. As a result, the seemingly eco-friendly concept of low-temperature washing turned out to be less sustainable than hoped. Today, 50 °C processes are being promoted as a more balanced solution – offering a compromise between resource conservation and environmental protection.

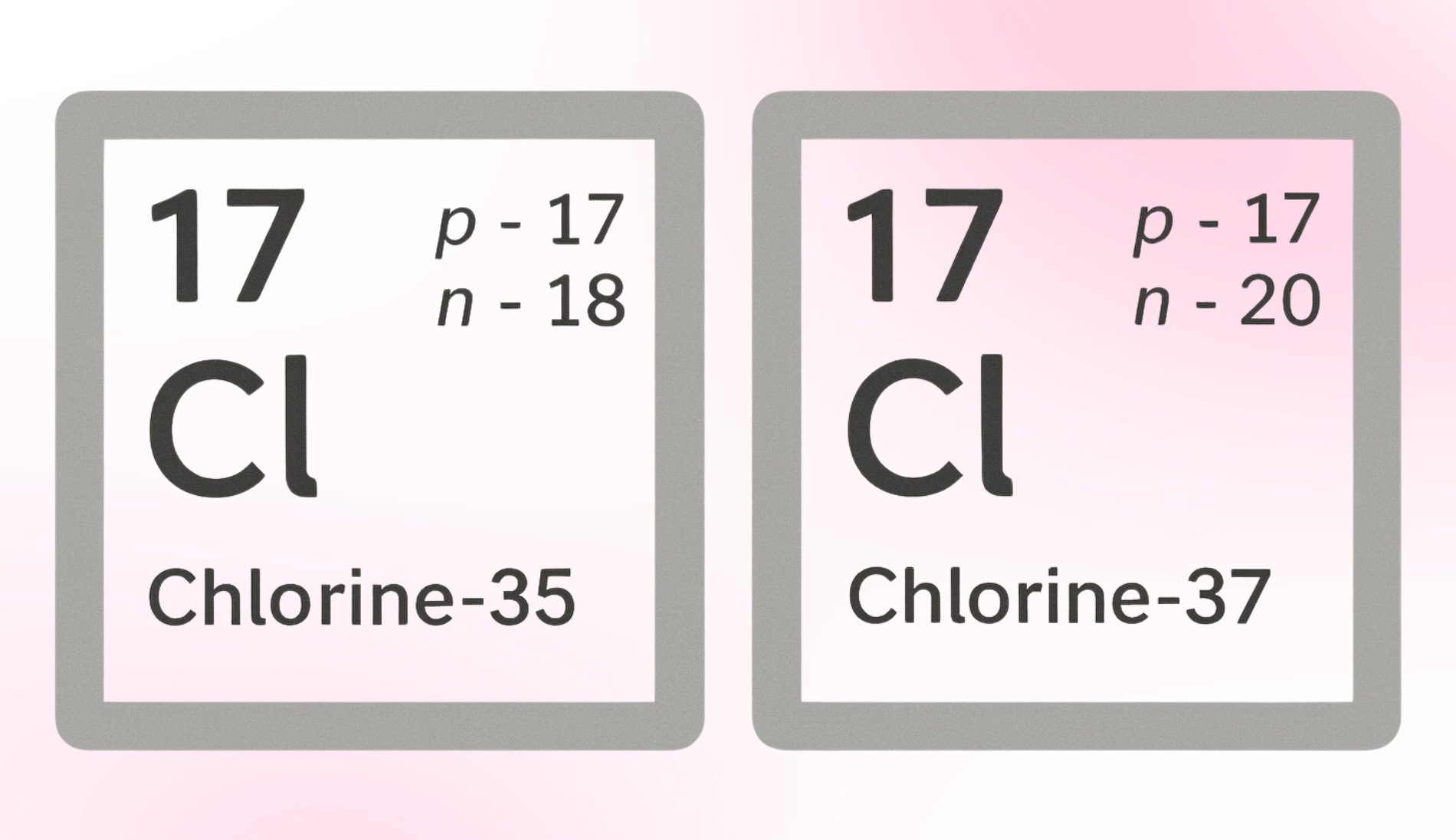

Highly Effective – Without Chlorine

Washing doesn’t work without chemistry – but it can work with less. For example, when an oxygen-based oxidising agent is activated using UV-C light, or when disinfecting ozone is injected into the rinse water. Because these methods do not rely on chlorine-based additives, they offer notable ecological benefits: reclaimed process water does not require dechlorination before reuse, and wastewater values such as COD, AOX and TOC are significantly lower compared to chlorine-based processes. An added bonus: the laundry doesn’t smell like a public swimming pool.

Remote Monitoring – Keeping an Eye on Dosing Accuracy

As detergents and auxiliary agents continue to evolve, dosing technology is becoming increasingly important. These systems ensure precise timing and quantity when dispensing substances into machines. However, their performance depends both on the interface between dosing unit and machine, and on the people operating them. Unauthorised changes to dosing volumes, poorly maintained pumps, unnoticed empty containers or switched chemicals can all have a serious impact on cleaning quality – and drastically increase the amount of rewashed laundry.