Reading time: 5 minutes

At the end of April 2023, a fire broke out at a laundry in Dresden, followed five months later by another incident at a textile care operation in Walldorf. In November 2024, a major fire caused damage running into millions at a facility in Bad Driburg; shortly afterwards, a business in Landstuhl went up in flames. Such catastrophic incidents are by no means confined to Germany. Around the world, fires break out in textile care operations, destroying parts of facilities and often causing losses amounting to millions. One of the main causes of fires in laundries is attributed to the spontaneous self-ignition of textiles. This essentially depends on three factors: the presence of a combustible material, the availability of an oxidising agent and a source of heat.

Basic Conditions for Fire Are Met in a Laundry

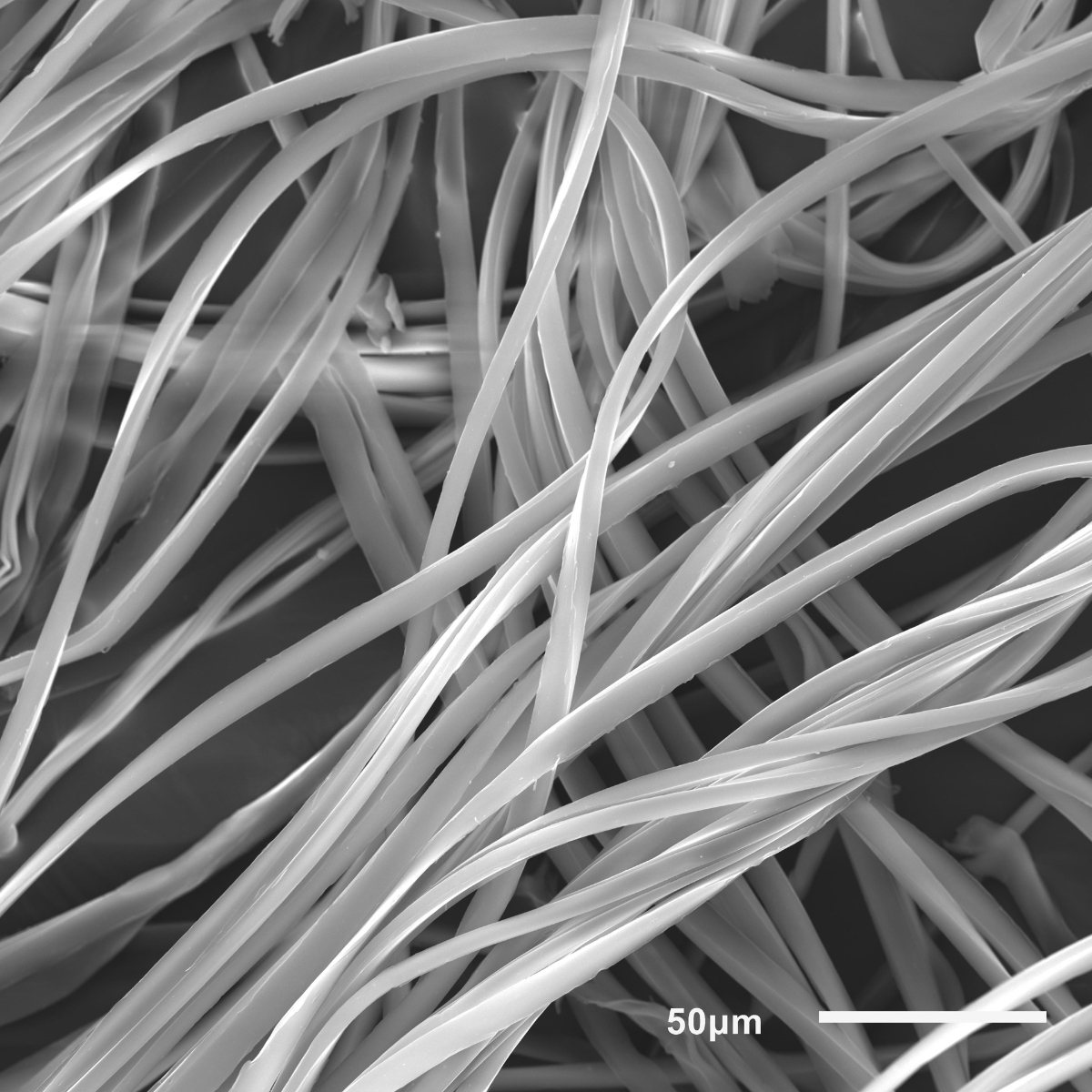

Workwear from workshops is often heavily soiled. These stains cannot always be completely removed, even during washing, and therefore pose a risk not only on the soiled side of a laundry’s goods reception area, but also on the clean side.

Oxidising agents are part of the basic equipment in laundries processing institutional textiles. In theory, residues of oxidising substances may remain on the textiles if wash processes are incorrectly set or dosing systems are defective, thereby increasing the risk of spontaneous ignition. However, it is particularly important to note that an oxidation process can also be triggered by the textile itself. In the case of cotton, for example, this process starts at a surface temperature of around 95°C, releasing heat. The resulting temperature rise further accelerates the oxidation process, which inevitably leads to the ignition of the combustible material.

The third factor, the heat source, may be a dryer, for example. Numerous fires start directly in machines – but not only there. Spontaneous ignition can also occur in discharged laundry batches and textile stacks. If these are not sufficiently cooled and are discharged at elevated temperatures, heat build-up occurs, with potentially fatal consequences. Another heat source that causes laundry and laundry facility fires in southern regions is the sun. It provides the energy required to ignite laundry containers stored outdoors on company premises, as reports from the USA have shown.

Associations Provide Guidance on Risk Prevention

Negative experiences with laundry fires have prompted industry stakeholders around the world to publish guidance on risk prevention:

- In the UK, NFU Mutual Risk Management Services Ltd. published the guide “Fire Safety Guide to Laundry Rooms” in 2021.

- The UK-based Textile Services Association (TSA) released the guides “Fire Safety Management – Laundry Equipment” and “Fire Safety – A Guide to Safely Managing Fire” in June 2025. Both publications can be downloaded free of charge from: https://tsa-uk.org/doclibrary/

- The US industry association TRSA offers, among other resources, podcasts and webinars aimed at improving fire safety in operations.

- Vero Insurance New Zealand, a New Zealand-based insurer, provides guidance on preventing fires in industrial laundries.

A Holistic Approach to Risk Assessment

The guides listed above mainly contain practical recommendations on laundry handling. These range from washing with warm water to improve the removal of oils and fats, to cooling down loads after drying. As a rule, however, such guidelines tend to overlook building services and plant technology, even though, based on the many years of experience of Katharina Meyersrenken, these play a decisive role in minimising the risk of laundry fires.

The textile care industry has known the Board Spokesperson of Versteegen Assekuranz (Bonn) for 30 years. Over this period, she has insured numerous laundries and handled a wide range of laundry fire cases. These incidents do not always end favourably for the businesses concerned – especially if insurance-relevant regulations have not been complied with. In such cases, a laundry operator may be assigned contributory negligence for the insured loss incurred, even if the fire was caused by arson, i.e. external third-party interference.n.“

Electrical Systems Require Special Attention

Another often underestimated aspect is non-compliance with the accident prevention regulation “Electrical Installations and Equipment” issued by the German Social Accident Insurance (DGUV). Katharina Meyersrenken explains the requirements: “Electrical installations and equipment must be in a safe condition and must be maintained in that condition. Employers are responsible for ensuring that both fixed and portable electrical installations are inspected for proper condition by a qualified expert – usually a certified electrician. This applies prior to initial commissioning, after any modification or repair and before recommissioning, as well as at regular intervals thereafter. When settling claims, we repeatedly find that inspection and verification of electrical installations are missing, which can have unpleasant consequences for the insured.”

No Installations on Hall Roofs Without Expert Assessment

A more recent insurance-relevant risk arises from the installation of photovoltaic (PV) systems on the roofs of laundry facilities. During installation, the protective function of roofs and fire walls must not be compromised. Nevertheless, there have been cases where fire protection requirements were not adequately taken into account and PV systems were installed on hall roofs insulated with combustible materials. Once a fire has started, it can spread extremely quickly and largely unnoticed in such structures. In addition, firefighting conditions are significantly more difficult, allowing the fire to spread further. Katharina Meyersrenken therefore emphasises that any installed PV system should be approved by a qualified expert and that this electrical installation must be subject to regular inspections.

Fire Protection Measures and Cleanliness Are Essential, Access Controls Are Helpful

Throughout her long professional career, she has repeatedly encountered a lack of fire protection measures in laundry operations. “Bag conveyor systems pose a high risk in the event of a fire. Ideally, a laundry should therefore be equipped with a sprinkler system; for facilities with an operating area of 5,000 m² or more, this is mandatory. If a company without fire protection systems wishes to take out insurance with us, we assess whether retrofitting is feasible or whether protection can be ensured through alternative measures, such as fire detection systems, fire walls or appointed fire safety officers.”

The dust that is unavoidable in laundries is also subject to critical assessment. Are lint and dust hanging from ceilings, machines and pipelines, with dust bunnies covering the floor? Or do ceiling fans blow these accumulations down so that they can be vacuumed up immediately? Cleanliness is an important decision criterion for insurers, as it can significantly reduce the risk of fire.

The list of measures to prevent fire risks could be extended further. However, in light of recent incidents, Katharina Meyersrenken highlights one additional aspect: “External contractors are frequently present in laundries. Recently, such a company caused a major fire by mishandling a tool – using an angle grinder instead of cutting shears – which set textiles alight. I therefore recommend that laundries introduce access controls for external visitors.”