Reading time: 4 minutes

In the textile care industry, energy sources are indispensable. They are required in the form of heating oil or gas to generate steam or hot air for heating washing liquors or drying and finishing laundry. Electricity, on the other hand, powers the motors of the entire machinery, drives conveyor systems, produces compressed air, and increasingly powers vehicle fleets. Consequently, the energy consumption of a laundry is high: in a medium-sized operation, the daily energy demand roughly equals that of a four-person household for an entire year.

With energy and fuel costs continuing to rise — according to the German Textile Cleaning Association (DTV, Bonn), they already accounted for 15 percent of total operating costs in 2024 — the industry must save resources wherever possible. Added to this is the European Commission’s goal of achieving climate neutrality by 2050 and reducing emissions by 55 percent by 2030 compared to 1990.

A Commercial Laundry with Strong Sustainability Goals

A company that has followed this guiding principle in a particularly consistent way is RUESS Textile Rental & Care in Wolfsburg. Since the construction of its hotel laundry in the mid-2010s, the owner family has invested in state-of-the-art technology that enables the reuse and optimal utilisation of resources, thereby reducing emissions. The company’s sustainability concept naturally includes heat exchangers and the recirculation of washing liquors, as well as the electrification of its vehicle fleet and the installation of a photovoltaic system designed to cover the facility’s daily energy demand. Above all, however, the laundry features a true innovation: one of its two continuous batch washers was equipped — even before its official market launch in 2018 — with the patented Smart UV Power System developed by CHT Beitlich (Tübingen). By irradiating oxidising washing liquors with UV-C light, this technology multiplies the formation of hydrogen peroxide, maximising its disinfecting and soil-dissolving effects.

UV-C Treatment for Washing Liquors

The activation of the liquor takes place in a 10-litre UV-C reactor. The wash water, to which the required amount of hydrogen peroxide for the washing process has previously been added, is pumped through the reactor. The liquor then flows through the reactor, where it is irradiated with UV-C light, and the hydrogen peroxide activation takes place. It is then conveyed into a tank, where it circulates several times. From there, the wash water is fed into the main wash.

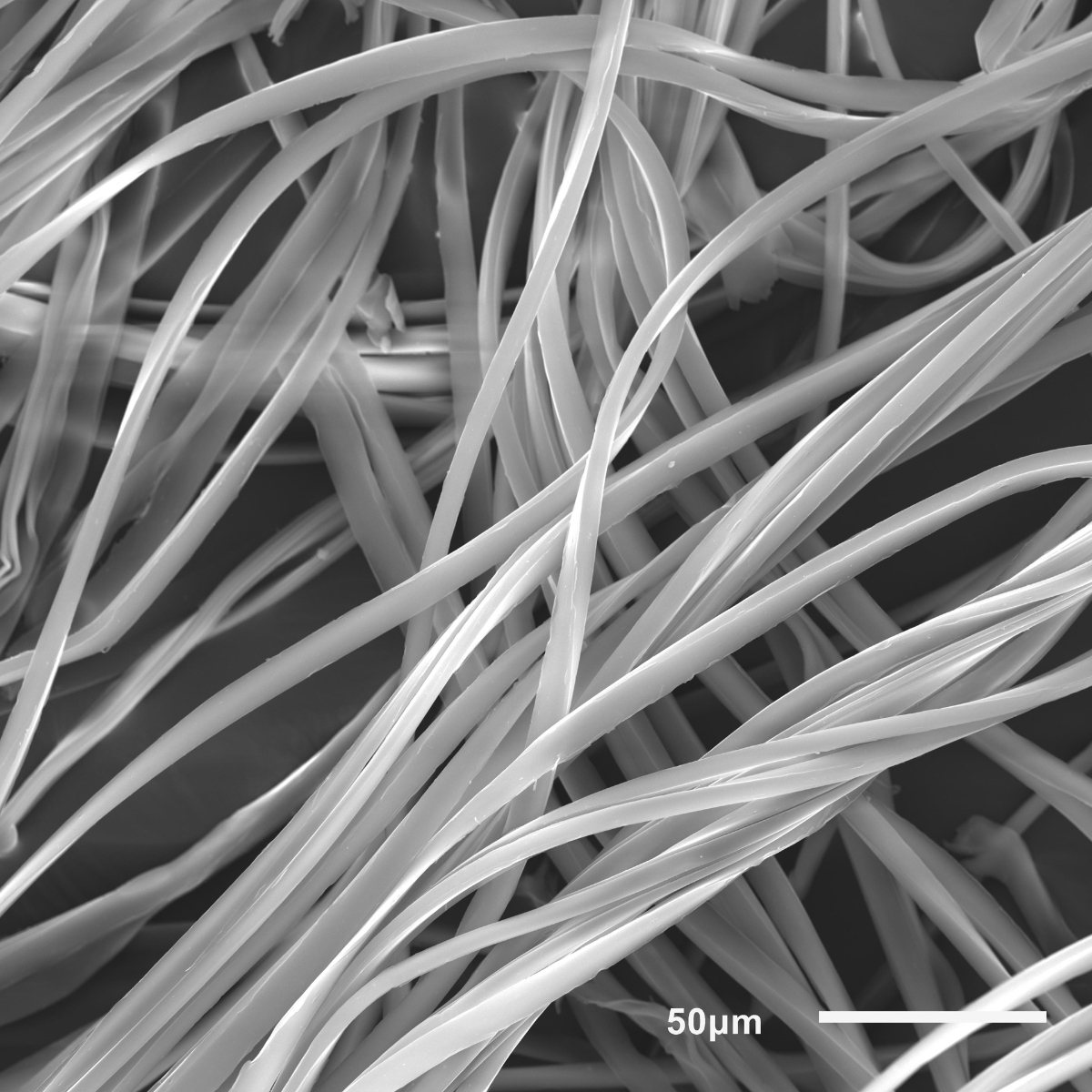

Since UV-C irradiation goes hand in hand with a reduced dosage of hydrogen peroxide, the process offers, in addition to ecological and economic savings, another advantage: the laundry passed into the rinse chamber carries less chemical residue, which improves the rinsing result. As a result, the amount of fresh water required has decreased by about 1 litre per kilogram of laundry on average.

“A significantly greater benefit, however, lies in the reduced energy demand resulting from the lower washing temperature. We can carry out chemical-thermal disinfection not at 70 °C but at 60 °C. This has reduced the heat requirement of the UV-C-reactor-equipped continuous batch washer, which pays off in several ways. On the one hand, we save a high four-figure amount annually; on the other hand, our CO₂ footprint is reduced. In addition, our wastewater is less polluted; the chemical oxygen demand (COD) and the total organic carbon (TOC) have decreased by 10 to 15 percent. For these reasons, we plan to retrofit our second washing line with UV-C technology in the near future,” reports Oliver Köhler, Production Manager at RUESS Textile Rental & Care.

Hygienically Processed Hotel Linen with Quality Certification

That the textile service provider in Wolfsburg uses a disinfecting washing process is rather unusual, as such a procedure is not required for hotel textiles. “The hygienic processing of our table, bed and terry linen according to RKI-listed procedures, combined with an additional backup mechanism through the Smart UV Power System, is our special quality feature. In addition, our company has long been certified according to the RAL Quality Mark (RAL-GZ 992/1), which ensures high-quality reprocessing of the linen. By combining precise process control and disinfecting procedures, we ensure that our customers receive only hygienically flawless textiles, which can be used safely in all hotel areas — provided, of course, that no one fails to suppress a sneeze when passing the laundry trolley,” says Daniel Simon, Business Unit Manager for Hotel & Catering at RUESS Textile Rental & Care, with a wink.

A Forward-Looking Use of Innovation

The regular inspections by the laundry experts of the Quality Mark Association, as well as tests carried out by CHT, have revealed further advantages of the Smart UV Power System. Because the high proportion of active oxygen significantly enhances the washing effect, the linen naturally achieves a very high degree of whiteness. As a result, only minimal amounts of optical brightener are used in the washing process — benefiting wastewater quality standards. In addition, fibre damage has been reduced, allowing the textiles to be used for longer.

The early decision by RUESS Textile Rental & Care to rely on an innovative and sustainable technology has therefore paid off — for both ecology and economy alike.