Reading time: 4 minutes

Thermal energy is the be-all and end-all of any laundry operation. It is required to heat wash water, and for drying, ironing and finishing textiles. Depending on the operating concept, the necessary heat is usually generated either decentrally in steam boilers or centrally via gas burners installed on the machines. This is the standard approach. However, there are textile care operations in which gas and steam are unsuitable or only acceptable with restrictions. This applies, for example, to laundries in nuclear power plants. “Gas firing systems pose a fire and explosion risk in a nuclear facility and are therefore subject to an additional, complex layer of safety and approval requirements. Gas-carrying pipelines can also represent a safety risk and are simply undesirable in sensitive areas of a nuclear power plant,” explains Sebastian Hatz, Sales Director DACH at Gottlob Stahl Wäschereimaschinenbau (Sindelfingen). “Steam, in turn, creates other challenges. If it is generated in a nuclear reactor, it may be radiologically classified and must under no circumstances be used for laundry applications. The process steam circuits then have to be separated at great expense, which some operators choose to avoid. For this reason, steam may not be available in all areas of the power plant – including the laundry. To circumvent the difficulties associated with steam and gas, laundry machines are therefore usually electrically heated.” This approach offers several advantages: since electricity is generated directly on site in a nuclear power plant, it is available in sufficient quantities. “In addition, electric heating of washing machines and dryers allows for very precise temperature control and regulation. Above all, in the event of a malfunction, the system can respond immediately and the power supply can be shut down quickly,” adds Sebastian Hatz.

A special kind of closed-loop system

Safety is the decisive factor in any nuclear facility, which is why additional regulations apply to the supply and disposal systems required to operate an in-house laundry. As the textiles to be processed (workwear, protective clothing and cleaning cloths) may be contaminated with radioactive particles, everything prefixed with the word “waste” requires special handling. “The wastewater from the washing machines must be collected and stored in a cistern. It is then evaporated, the resulting vapour filtered and fed back into the reactor system. The remaining residues are contaminated hazardous waste and are placed in a CASTOR container suitable for final disposal,” explains Sebastian Hatz, who has overseen the installation of several laundries in nuclear facilities at Gottlob Stahl Wäschereimaschinenbau. “Exhaust air cannot simply be discharged either – it is cleaned using mechanical filters to remove radioactive substances that may be bound in dust and aerosols as effectively as possible. Only then can it be released outside via the exhaust air system. The filtered residues must also be treated as radioactively contaminated hazardous waste.”

Contaminated textiles remain on site

Given the special conditions that apply to a laundry in a nuclear facility, the question arises as to why textiles are processed on site at all rather than outsourced to an external service provider. After all, so-called inactive laundry such as terry towels is washed externally in Switzerland. However, this option no longer applies once textiles such as workwear, protective clothing or cleaning cloths from maintenance cleaning may be contaminated with radioactive particles. As these high-energy particles pose significant risks to employees and the environment, the textiles must not leave the site and processing must be organised by the operator. Laundry care therefore takes place in in-house laundries equipped with the necessary protective measures, where special decontamination processes are applied using clean/dirty separation and specialised detergents, and hazardous substances are safely disposed of. In this way, radiation protection, occupational safety and operational safety are ensured.

Avoiding particles through carefully selected processes

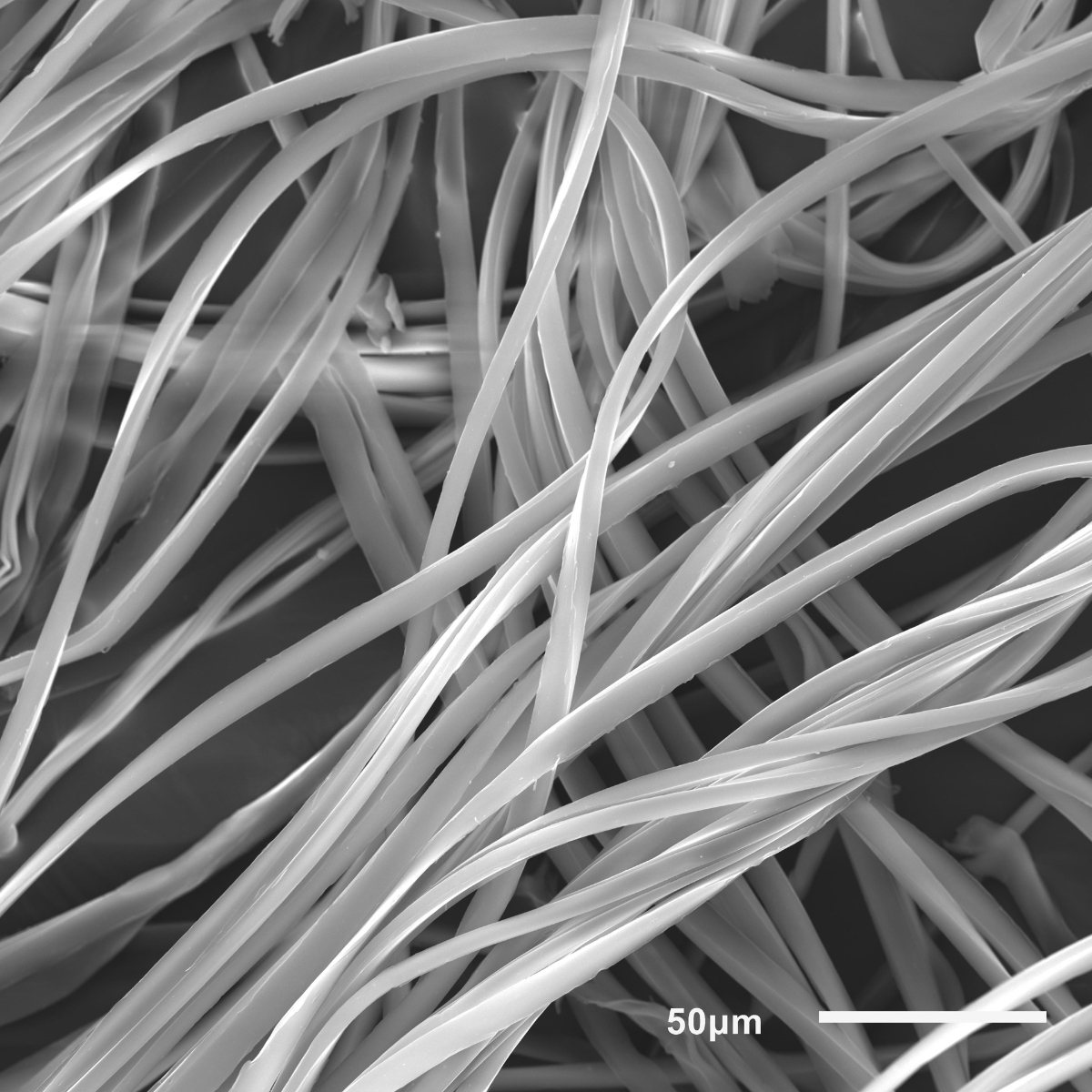

As in a conventional laundry, the machinery required in a nuclear power plant depends on the number of employees, clothing change intervals, the equipment provided to staff, hygiene and decontamination requirements, the cleaning schedule and the intensity of textile use. Apart from generally manageable laundry volumes, the two types of operation are therefore quite comparable. When selecting machinery, however, Sebastian Hatz recommends washing machines that allow separation between the contaminated and clean sides. “It is also important that the machines have smoothly finished surfaces to minimise the risk of contamination build-up. For drying reusable protective clothing used in a nuclear facility, we also recommend a drying cabinet, which we offer in two sizes. A drying cabinet works without mechanical action, which reduces lint formation and the release of dust-bound particles into the surrounding air. If workwear and protective clothing are dried in a tumble dryer instead, we configure suitable programmes to prevent unnecessary material wear or the risk of fire due to overheating.”

Special safety precautions for personnel

Although professional laundry machines are very durable, they do not last forever and must be repaired or replaced when necessary. However, a service technician cannot simply walk into a nuclear power plant to carry out such work. Sebastian Hatz explains the required measures: “Only authorised personnel trained in radiation protection are granted access to the relevant areas. Our technicians receive comprehensive radiation protection training and hold a radiation protection pass. In addition, we always obtain information about the power plant’s radiation protection organisation, which is binding for our personnel. This includes, for example, access controls, wearing a dosimeter and personal protective equipment, specified time limits for stays and clearance measurements of radioactively contaminated materials. When working in a nuclear facility, such precautions are essential for protecting the health of our employees.” And anyone who thinks that, with countries such as Germany phasing out nuclear power, laundries in nuclear facilities will soon no longer be required is mistaken. The plants are being decommissioned – and this process takes an average of ten to twelve years. Until then, laundry operations will continue.